TM 5-3895-373-34

E.

ASSEMBLE Continued.

5.

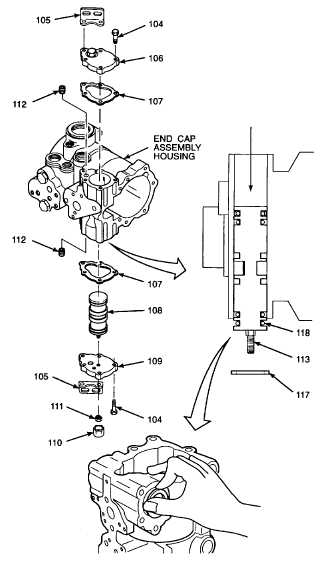

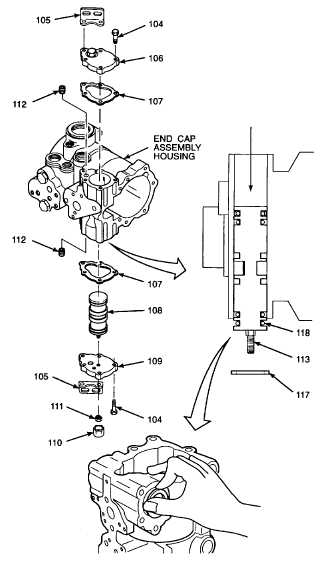

INSTALL SERVO PISTON.

a.

Turn end cap assembly housing on side.

Hydraulic oil can be moderately flammable

and can be an irritant to the skin, eyes, and

respiratory

system.

Avoid

prolonged

exposure. Eye protection and rubber

gloves must be worn when working with

hydraulic oil.

b.

Lubricate servo piston (108) with clean hydraulic

oil.

Sharp edges on end cap assembly housing

can damage piston ring during servo piston

installation. Do not slide servo piston

through end cap assembly housing further

than necessary to install piston ring. Poor

or erratic pump operation can result from

damage to piston rings.

Ensure servo piston is oriented correctly in

end cap assembly housing. Propulsion

pump cannot be correctly assembled if

servo piston is installed incorrectly.

c.

Slide servo piston (108) into end cap assembly

housing until piston emerges slightly from

opposite side.

d.

Lubricate piston ring (117) with petrolatum.

e.

Install piston ring (117) over the top of preformed

packing (118) on servo piston (108).

f.

Slide servo piston back into end cap assembly

housing.

g.

Install plugs (112) into end cap assembly

housing.

h.

Install gaskets (107).

i.

Thread servo cover (109) onto servo piston

(108).

j.

Install hex nut (111) onto servo cover (109). Do

not tighten at this time.

k.

Install hex head cap screws (104) through lift

brackets (105), servo covers (106 and 109), and

gaskets (107) into end cap assembly housing.

Tighten cap screws to 11 lb-ft (16 N•m) using

screwdriver bit set.

NOTE

Centering the servo piston is a preliminary

neutral adjustment. Final adjustment is

made during calibration, after propulsion

pump is installed and connected to the

engine.

I. Position servo piston in approximate center of

travel by turning special screw (113) with an

allen wrench. Install cap (110).

GO TO NEXT PAGE

2-417