TM 5-3895-373-34

E.

ASSEMBLE - Continued.

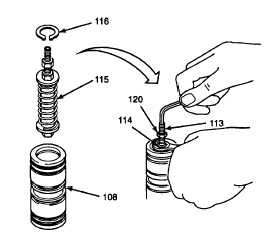

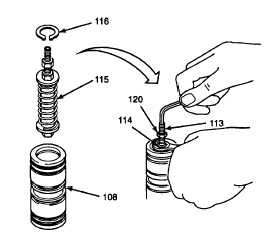

3.

INSTALL SERVO SPRING INTO SERVO PISTON.

Hydraulic oil can be moderately flammable

and can be an irritant to the skin, eyes, and

respiratory

system.

Avoid

prolonged

exposure. Eye protection and rubber

gloves must be worn when working with

hydraulic oil.

a.

Lubricate all parts with clean hydraulic oil.

b.

Slide servo spring (115) into servo piston (108).

c.

Use an allen wrench and hold special screw

(113) on

servo spring from turning.

d.

Compress servo piston by tightening hex nut

closest to servo spring with a wrench. Be sure

to expose the complete internal retaining ring

groove. Use two flat-blade screwdrivers to

further compress servo spring to

allow

retaining ring (116)to be installed.

Use care when installing snap and retaining

rings.

Snap and retaining rings are

under spring tension and can act as

projectiles when released and could cause

severe eye injury.

e.

When spring is compressed, install retaining ring

(116).

f.

If retaining ring cannot be installed,

additionally compress servo spring by tightening

inner hex nut.

Be sure retaining ring is fully seated in

groove. Propulsion pump control will be

lost if retaining ring is not fully seated in

retaining ring groove.

g.

Ensure retaining ring is fully seated in retaining

ring groove.

Neutral position cannot be obtained in

propulsion pump if any looseness exists

between servo spring and servo piston.

Ensure servo spring is correctly tightened

and seated inside servo piston. Equipment

damage

may

result

from

improper

installation of servo spring inside servo

piston.

h.

If hex nut (114) is overtightened, servo spring will

be loose in servo piston. Loosen hex nut.

i.

If hex nut (114) is undertightened, special screw

will be loose between spring guides. Tighten

hex nut.

j.

When servo spring is correctly seated inside

servo piston, hold inner hex nut (114) from

turning and tighten outer hex nut (120) against

inner hex nut (114) to 22 lb-ft (30 N•m) to lock

servo spring in position.

GO TO NEXT PAGE

2-415