TM 5-3895-373-34

2.30

REPLACE/REPAIR PROPULSION PUMP - Continued.

E.

ASSEMBLE.

1.

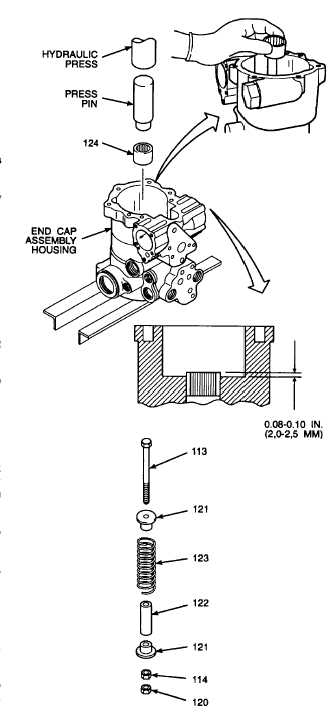

INSTALL NEEDLE BEARING.

Oils from skin and moisture can cause

corrosion on needle bearings. Do not

handle bearings with bare hands. Wear

cotton gloves when handling bearings.

a.

Place end cap assembly housing on hydraulic

press frame.

b.

Insert needle bearing (124) into end cap

assembly housing.

Ensure printed (numbered) end of needle

bearing faces bearing press pin. Do not

install

needle

bearing

with

printed

(numbered) side down. Damage to needle

bearing and end cap assembly housing

may result from improper installation.

c.

Insert press pin into needle bearing (124),

resting against outer race.

d.

Align needle bearing (124) with bore on inside

end cap assembly housing.

e.

Press needle bearing (124) into position.

f.

Remove press pin from needle bearing (124).

g.

Use a micrometer depth gage and check needle

bearing protrusion from inside surface of end

cap assembly housing. Bearing should protrude

0.08 to 0.10 in. (2,0 to 2,5 mm).

2.

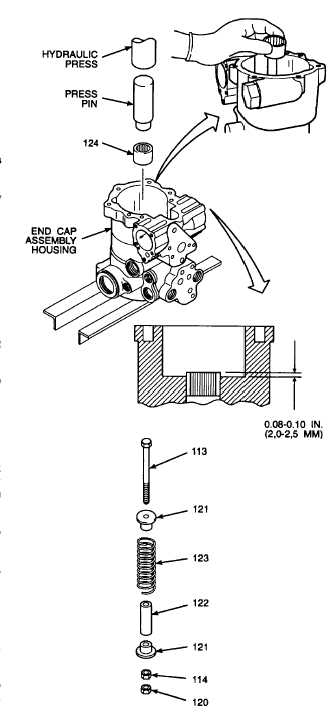

INSTALL SPECIAL SCREW, SERVO STOP, AND

SPRING GUIDES ON SERVO SPRING.

a.

Install one spring guide (121), servo stop (122),

servo spring (123), and second spring guide

(121) on special screw (113).

b.

Install hex nuts (114 and 120) on special screw.

c.

Use a wrench and hold special screw (113) from

’ turning.

d.

Tighten hex nut (114) closest to servo spring

(123) to compress servo spring. Tighten until

light resistance is felt.

GO TO NEXT PAGE

2-414