TM 5-3895-373-34

2.

REPLACE/REPAIR PROPULSION PUMP - Continued.

D.

INSPECT Continued.

4.

INSPECT SERVO BORE IN END CAP

ASSEMBLY HOUSING FOR NICKS, SCRATCHES,

AND SIGNS OF CONTAMINATION.

a.

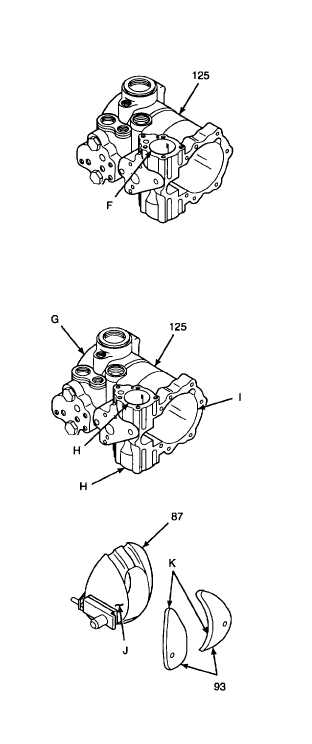

Use a strong light and inspect servo bore,

surface F, inside end cap assembly housing

(125) for nicks or scratches that can be felt with

a fingernail and signs of contamination.

b.

Use emery cloth to remove nicks and scratches

that can be felt with a fingernail. Clean end cap

assembly housing (125) after removing nicks

and scratches. Refer to cleaning procedure.

c.

Replace end cap assembly housing (125) if any

signs of contamination or pitting are detected or

if nicks and scratches cannot be removed with

emery cloth.

5.

INSPECT SEALING SURFACES IN END CAP

ASSEMBLY HOUSING.

a.

Visually inspect sealing surfaces G, H, and I on

end cap assembly housing (125) for nicks,

scratches, or any damage that can prevent

proper sealing.

b.

Replace end cap assembly housing (125) if

nicks, scratches, or damage can prevent proper

sealing when propulsion pump is assembled.

6.

INSPECT SWASH PLATE AND SLEEVE

BEARINGS

FOR

NICKS,

SCRATCHES,

AND

SCORING.

a.

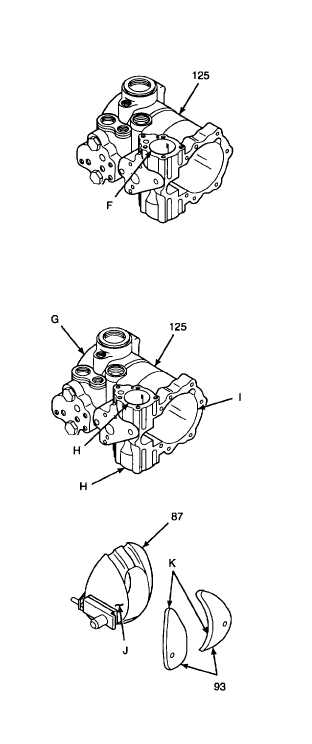

Inspect swash plate (87) and sleeve bearings

(93), surface J and K, for nicks, scratches, and

for scoring.

b.

Use emery cloth to remove nicks and scratches

from swash plate (87). Clean swash plate after

removing nicks and scratches. Refer to cleaning

procedure.

c.

Replace swash plate (87) if nicks and scratches

cannot be removed with emery cloth or if scoring

is detected.

d.

Replace sleeve bearings (93) if nicks, scratches,

or scoring is detected.

GO TO NEXT PAGE

2-412