TM 5-3895-373-34

E.

ASSEMBLE Continued.

10.

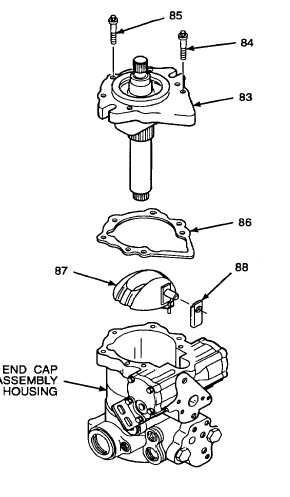

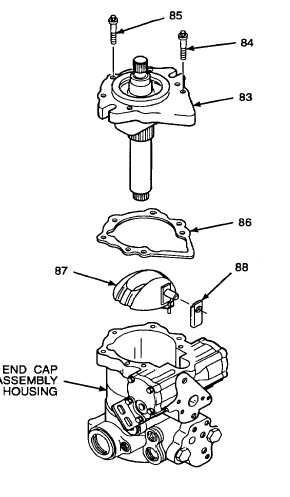

INSTALL SWASH PLATE, GASKET, AND FRONT

COVER.

a.

Turn end cap assembly housing on end to allow

front cover (83) installation while facing up.

Hydraulic oil can be moderately flammable and

can be an irritant to the skin, eyes, and

respiratory system. Avoid prolonged exposure.

Eye protection and rubber gloves must be worn

when working with hydraulic oil.

b.

Lubricate cylinder block assembly with clean

hydraulic oil.

NOTE

Sleeve bearing must be installed to allow

clearance for sleeve bearings on front cover.

c.

Install sleeve bearing (88) onto swash plate (87).

NOTE

When installed, swash plate must rest flush on

cylinder block assembly and sleeve bearing

must engage large center groove on servo

piston.

d.

Install swash plate (87) into end cap assembly

housing.

e.

Install gasket (86) onto end cap assembly

housing.

All parts must be properly aligned before front

cover screws are installed. Do not force front

cover into position if front cover is difficult to

position. Check alignment of internal parts prior

to installing front cover screws. Damage to

swash plate and front cover may occur if front

cover is forced into position.

Ensure sleeve bearings stay in position on front

cover during installation.

f.

Install front cover (83) onto end cap assembly

housing. Align pump shaft splines with cylinder

block splines. Pump shaft may need slight

rotation for spline alignment.

NOTE

When properly aligned, cylinder block

spring holds cover away from end cap

assembly housing a maximum distance

of 0.125 in. (3, 18 mm).

g.

Install screws (84) into front cover. Tighten

screws to 43 lb-ft (58 N.m).

h.

Install screws (85) into front cover. Tighten

screws to 67 lb-ft (91 Nom).

i.

Attach slip joint pliers to pump shaft. Rotate

shaft. Slight resistance should be noted when

turning pump shaft.

j.

If pump shaft does not turn or turns with no

resistance, remove screws from front cover,

remove front cover and swash plate and repeat

steps d through i as necessary.

GO TO NEXT PAGE

2-421