TM 5-3895-356-14&P

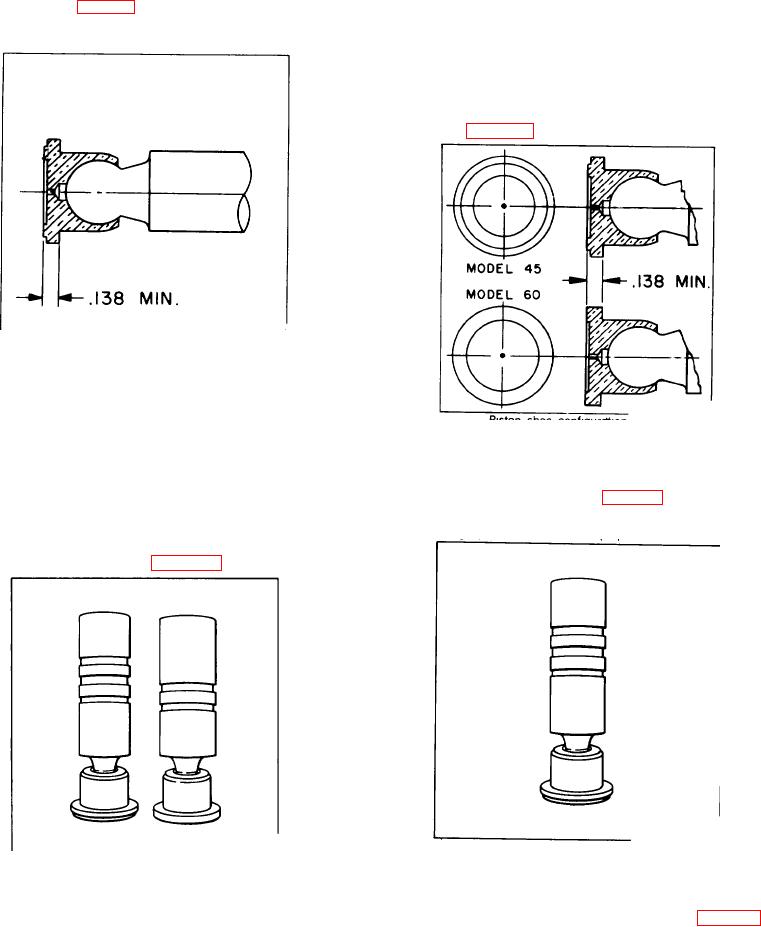

tolerance limits in Fig. 33. If piston shoe (18) does not

pistons may be refitted with two groove pistons again

fall within tolerance limits, discard reworked piston and

only as a nine piece set. Two groove and three groove

replace.

pistons must not be mixed in the same unit.

NOTE:

Model 45 and 60 pistons are easily

identified by characteristic piston

shoe running surface configurations.

See Fig. 138.

Figure 136.

Piston shoe rework tolerance

Check piston shoe for iron or steel particles imbedded in

the running surface. If present, discard the piston.

Often, large scratches on the piston shoe running

Figure 138.

surface will "heal over" if placed back in service. It is

Piston shoe configuration

recommended, however, that all piston shoes with badly

11. Inspect steel piston body. If any galling is apparent

scratched running surfaces be either reworked within

or if any irregularities can be felt with the fingernail, the

tolerance limits or replaced.

piston must be discarded. See Fig. 35. If damage is

NOTE:

apparent, check the corresponding cylinder block bore

Dynapower units may be encountered

(12) for similar damage.

with either two groove or three

groove pistons. See Fig. 137.

Figure 139.

Figure 137.

Inspecting piston body

Two groove and two groove pistons

Inspect piston return plate (19) for heat discoloration or

Units supplied from the factory with two groove pistons

cracks. Check for flatness. If discolored, cracked or

may be refitted with three groove pistons as a nine piece

distorted, replace with a new return plate. See Fig. 140.

set only.

12. Install piston assemblies (18) in piston return plate

In a like manner, units supplied with three groove

(19). Used pistons must be so positioned in

98