TM 5-3895-356-14&P

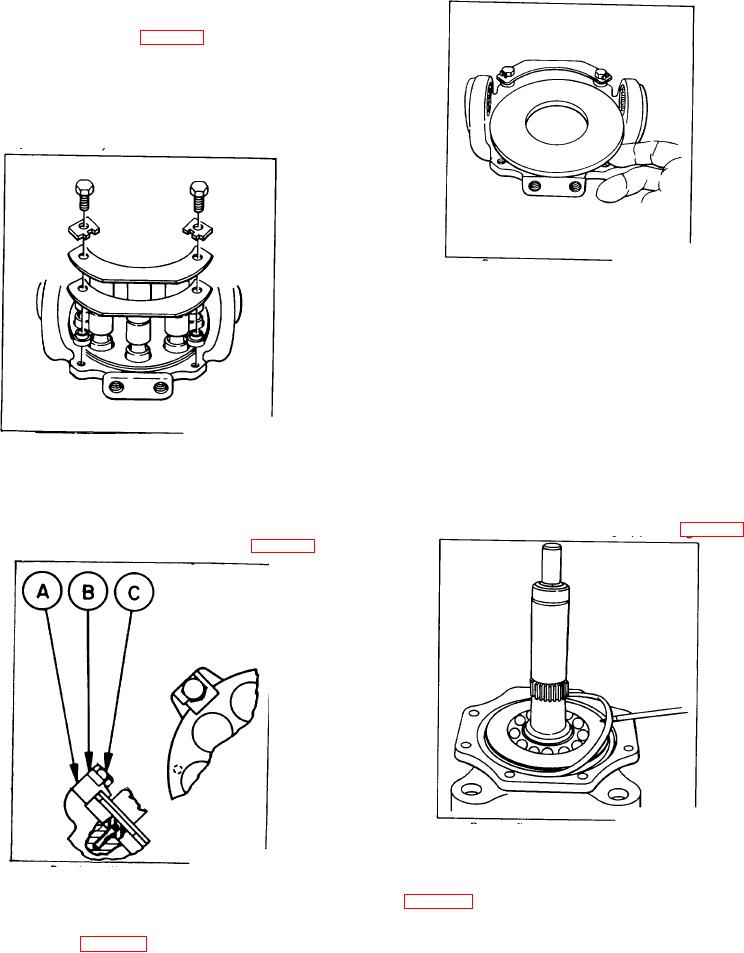

14. Remove two hex bolts (17) two tab lock washers

(16) and remove one clip (15), one bearing plate (14),

and two spacers (13). See Fig 112. Inspect bearing

plate (14). If wear is evident or there are scratches in the

bearing surface, discard bearing plate and replace. If

beating plate (14) must be discarded, disassemble other

return plate spacer and discard second bearing plate. If

bearing plate (14) is reuseable, do not disassemble

second return plate spacer, assembly.

Figure 124.

Removing cam reaction plate

16. Inspect cam assembly (12) for damage. Remove

any burrs or nicks from the face of the cam with a fine

stone.

Inspect trunnion bearings (23) for galling,

roughness, or cracked cages.

If damaged, press

trunnion bearings from cam (12) using an arbor press

and a plug 11/2" in diameter.

NOTE:

Figure 122.

On a major overhaul, replace

Return plate spacer disassembly

trunnion bearings (23), regardless of

EXCEPTION

conditions, as described above.

On older units, remove two hex bolts (A) tab lock

17. Remove O ring (31) from flange (2). See Fig. 125.

washers (B) and return plate guides (C). See Fig. 123.

Figure 125.

Removing flange square ring

18. Reverse mounting flange (2) and remove four hex

Figure 123.

bolts (3) (six where applicable) and lock washers (6).

Pre phase III return plate guides

See Fig. 126.

15. Slip out piston return plate (19) and piston

If the shaft seal retainer (57) has two 1/4" threaded

assemblies (18). Pick wear plate (20) from cam

pulling holes, use two 1/4" bolts and screw into-threaded

assembly (12). See Fig. 124.

holes until the gasket seal is broken.

94