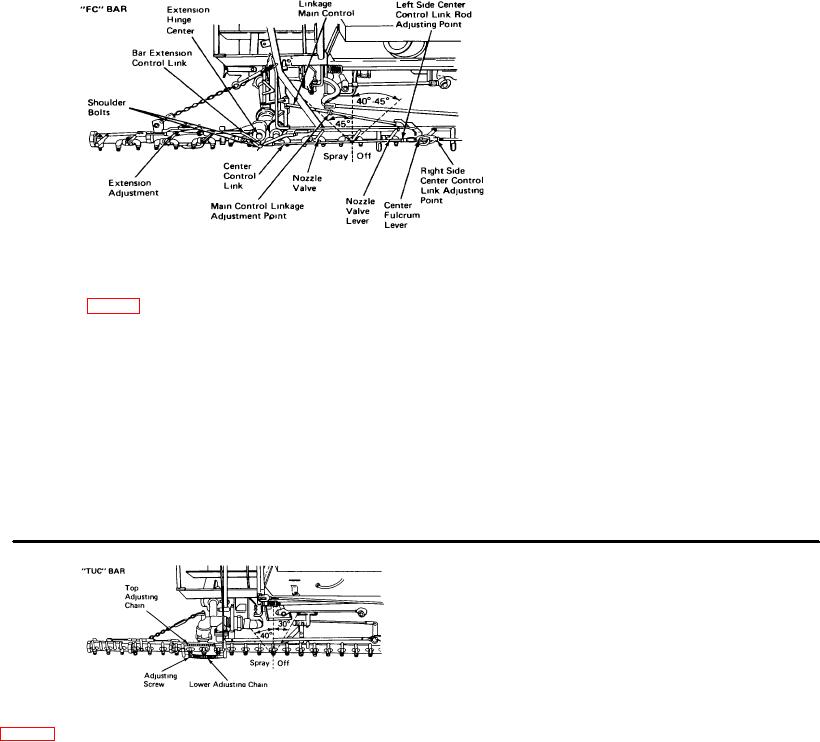

SPRAY BAR VALVE ADJUSTMENT

B. Align left side shoulder bolt

to center of extension lunge A rod

inserted through shoulder bolt hole to

extension hinge will aid in checking

alignment If necessary, heat and

bend bar extension control link to

obtain proper alignment.

Verify

proper alignment by raising bar with

rod or shoulder bolt in place-nozzle

valves should not move.

C. Check for proper nozzle

valve lever travel on center section

extension

and

any

additional

extensions The valve levers should

move 45 degrees to the left of

vertical and 40 degrees to 45

Figure 35

degrees to the right of vertical Adjust

if necessary

movement indicates worn linkage

Note Quadrant lever is

D. Connect left center control

that should be replaced

identified on Page 6.

linkage and adjust for proper left

3. Shoulder bolts that connect

1. Nozzle valve levers should

center section nozzle valve lever

bar extension control link to center

be 40 degrees to 45 degrees to right

travel

control link should center on

of vertical when quadrant control

E. Repeat steps B, C and D for the

extension hinge when valves are In

lever is to the left in "Circulate m Bar"

right side of bar

"Off" position

position and 45 degrees to left of

F.

Finally, adjust at main

If any discrepancy is found in

vertical when lever is in "Distribute"

control linkage, relationship of nozzle

the

preceeding,

correct

by

position

valve lever position to quadrant

completing the following spray bar

2.

Nozzle valve levers

control position, per item one

nozzle valve adjustment procedure

should start to move when quadrant

Do not fold extensions when

A. Disconnect main control

lever is moved 1" or less More

valves are turned on Do not attempt

linkage and both center control

to spray center of bar with extensions

linkages from center fulcrum lever.

folded without removing shoulder

bolts controlling extensions

the extension valve levers If

vertical and 40 degrees to left.

movement occurs or chains are not

tight, make the corresponding

adjustment having first disconnected

the chains on the lower left and

upper right

4. Throw quadrant lever to

spray position and extension valve

levers to 40 degrees left of vertical In

Figure 36

this position the lower left and upper

Note Quadrant lever Is identified on

right chains should be tight Since the

3.

Work

extension

lever arms operating the chains are

nozzle valves to check for binding,

1. Fold extensions back and

of different lengths, the lower left and

then throw valve levers 30 degrees to

adjust control linkage in

center

upper right will be loose when valves

right of vertical (off position) Turn

section so that valve levers are

are thrown to "Circulate In Bar"

quadrant lever to extreme left

vertical when quadrant lever Is 1" to

position, and the upper left and lower

position ("Circulate in Bar") Return

left of 45 degree position

right will be loose In the "Distribute"

extensions

to

the

forward

2. Throw quadrant lever to left

position When adjusted per above,

straightened position The adjustable

and right against stops and check

valves should work easily and there

connecting chains on the upper left

throw of nozzle valve levers Nozzle

should be no overload on the chain

and lower right should become tight

valve levers should turn through

pins.

but should not cause movement of

approximately 30 degrees to right of

27