TM 5-3895-356-14&P

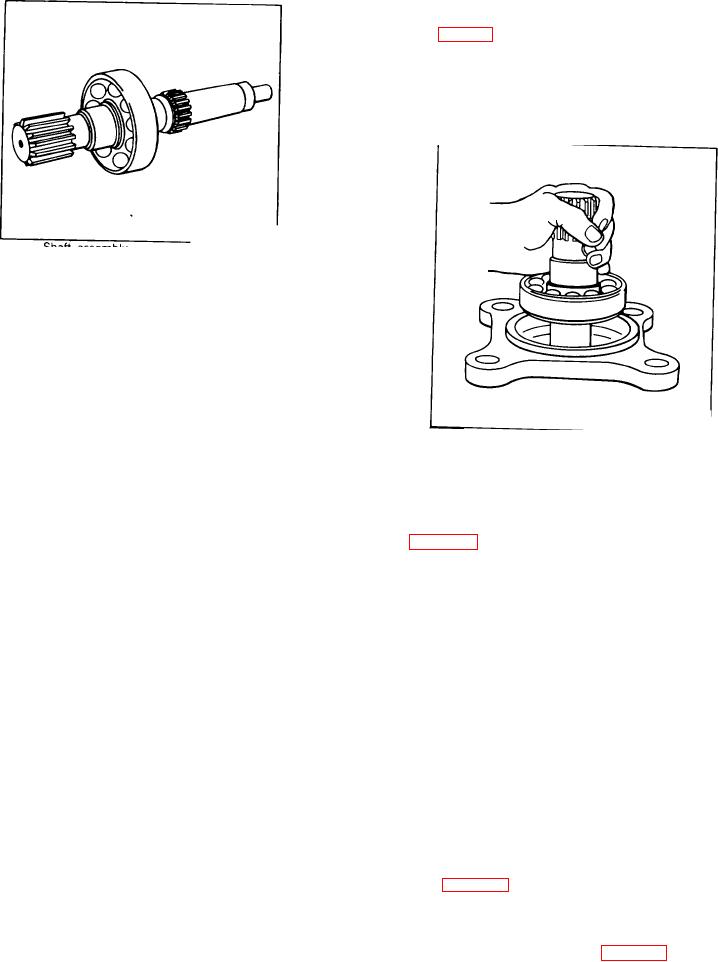

4. Install pump shaft assembly (1, 30, 55, 49 & inner

race of 50) through the front face of the mounting flange

(2). See Fig.131. The ball bearing (30) should fit snugly

in the. flange (2). If ball bearing (30) doesn't seat easily,

heat mounting flange (2) in hot oil and seat ball bearing

in proper position. Do not drive the ball bearing (30) into

place. Do not use the shaft seal retainer (57) to force

bearing into seat. Check bearing (30) for free running by

rotating shaft (1).

Figure 130.

Shaft assembly

replaced. The inner and outer race are serviceable as a

matched set only. Remove retainer ring (49). Slip inner

race from shaft (1).

This completes disassembly of the Dynapower pump.

PUMP ASSEMBLY

Keep Dynapower parts and work area absolutely clean at

Figure 131.

all times.

Installing pump shaft assembly

Shaft and bearing failures are often of a fatigue type. If

EXCEPTION

the pump has had considerable service life, replace

On units with an 8 inch square flange, the shaft

these parts as they may be close to the fatigue point.

assembly is installed through the back face of the flange.

Use new gaskets and seals, except as noted.

See Fig. 128.

A. Install pump shaft (E) and assembled parts

1. Inspect pump shaft (1) for excess wear or damage.

(F, G, H & J) from back of flange using

If either spline shows damage or if bearing journal or

procedure as described in Step (4) above.

seal surface shows galling, scoring or heat discoloration,

replace shaft.

B. Using truarc pliers, install retaining ring (D)

in adapter.

2. If inner and outer race of roller bearing (50) are not

5. Press a new shaft seal (56) into the retainer (57)

damaged or worn, assemble inner race on shaft (1) with

using an arbor press with a 21/2 inch plug and loctite

retaining ring (49) using truarc pliers. If either inner or

sealant. Fill cavity between oil lip and wiper lip

outer race is damaged, replace bearing as a set only!

approximately 3/4 full with Litholene Multi-Purpose

Install new inner race as described above.

grease. Install new square ring (29) in flange (2). To

prevent possible cuts or abrasion, the square ring (29)

3. If previously removed, install inner retainer ring (55).

should be lightly coated with a multi-purpose grease.

Inspect old ball bearing. If galled or damaged, press

Wrap shim stock or other thin material around shaft

new ball bearing (30) on pump shaft (1). Ball bearing

spline and carefully slide shaft seal (56) and retainer (57)

(30) should seat against inner retainer ring (55).

over pump shaft (1).

CAUTION should be exercised not to deform inner

EXCEPTION

retainer ring by forcing bearing (30) against it. If

In the absence of square ring shoulder, place new

deformed, back bearing (30) off and reseat. Care should

gasket (A) over pump shaft (E) and proceed as in Step

be taken to support inner race of ball bearing (30) in

(6). See Fig. 128.

arbor press while pressing in shaft (1). Heating the ball

bearing in hot oil will aid in a smooth bearing installation.

6. Line up bolt holes and secure seal assembly (57) to

Install outer retaining ring (55).

flange (2) with hex bolts (58) and lock washers (6).

Torque bolts to 132 in. lbs. See Fig. 132.

96