TM 5-3895-356-14&P

by pushing down on first one edge and then the opposite

edge of the wear plate in a rocking motion. If any

looseness is felt, remove cam plate and completely clean

and compressed air dry both the cam (12) and wear

plate (20) to remove any foreign particles from beneath

wear plate. Reposition wear plate in came (12) and

repeat above procedure. If wear plate (20) refuses to

seat properly, check plate for flatness and replace if

necessary.

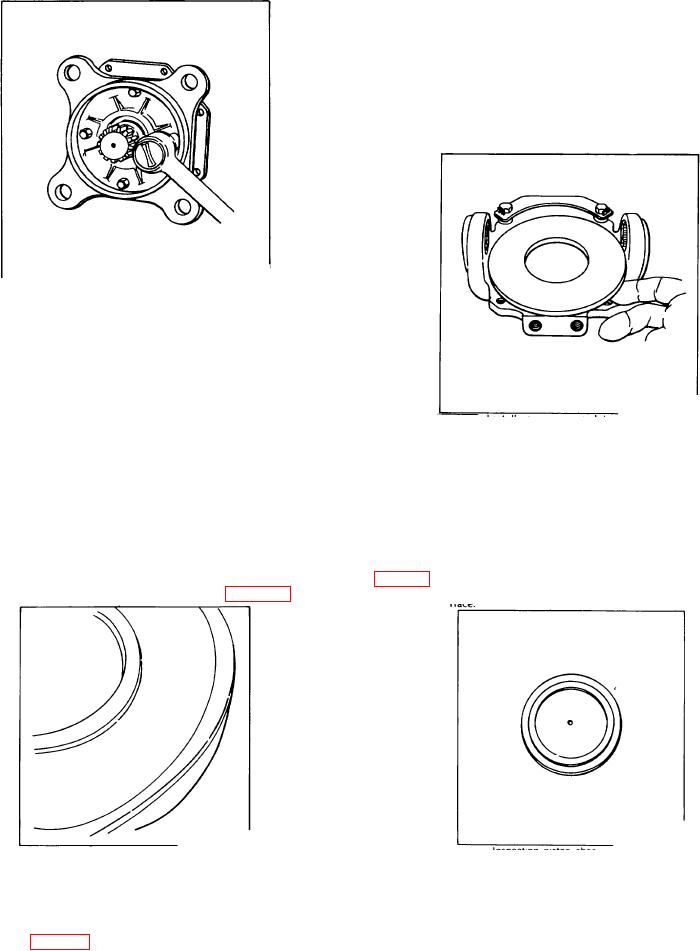

Figure 132.

Installing shaft seal retainer

7. If trunnion bearings (23) were removed from cam

(12) during disassembly, install new trunnion bearings

(23) using an arbor press and a 11/2 inch plug, pressing

against the lettered side of the trunnion bearing. It is

extremely important that the bearing be started straight

into the bore. If the bearing cocks at any time during

Figure 134.

assembly, remove and discard the bearing. Support the

Installing cam wear plate

cam lug on the under side to avoid bending the lug.

Outer face of trunnion bearing (23) should be pressed

10. With a push-pull motion, check for free play between

flush with outer face of cam (12).

bronze shoe and steel piston body. If any play can be

felt, the piston must be discarded. Inspect bronze piston

8. Examine wear plate (20).

Circular patterns

shoes (18). During normal service, a dulling of the

burnished on the surface of the cam plate are normal. If

running surface is to be expected. If large scratches,

circular patterns on the wear plate are extensive and can

that can be felt with a fingernail, are present, see

be felt with the fingernail, or if angular scratches are

Fig.135, make several short passes over 500 grit emery

evident, the plate must be discarded. See Fig. 133.

paper on a lap surface.

Figure 133.

Inspecting cam reaction plate

Figure 135.

Inspecting piston shoe

9. Match up dowl pin (34) in cam (12) with dowel pin

hole in wear plate (20) and seat wear plate (20) in

ON THE LAST FEW PASSES, PLACE 5-6 SHEETS OF

cam(12) See Fig.134.Check proper seating

EMERY PAPER AS A CUSHION UNDER THE TOP

SHEET

TO

OBTAIN

THE

PROPER

EDGE

SHARPNESS. Check the reworked piston shoe (18)

with

97