TM 5-3895-356-14&P

cover (9). Apply vaseline to O-rings (62) and install

surface to remove any high spots. Inspect charge pump

plugs (61) in cover.

spacer assembly (48). If any galling or excessive wear is

apparent, discard the spacer assembly (48).

See

Fig.153.Remove any burrs with a hard Arkansas stone or

equal to remove 'any nicks from the flat faces.

29. Position O-ring (41) over cover bearing (50).

Lubricate the entire charge pump cavity with clean

transmission oil.

30. Install lower valve plate (42) over cover bearing (50)

and O-ring (41). See Fig. 154.

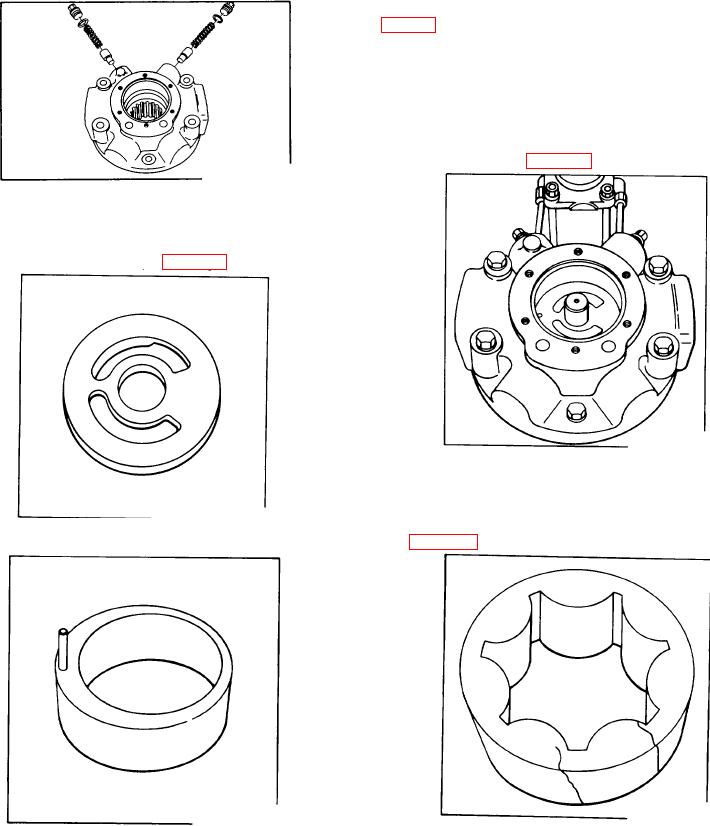

Figure 151.

Pump cover with assembled parts

28. Visually inspect upper (45) and lower (42) valve

plates. If circular wear patterns can be felt, discard both

the upper and lower plate. See Fig. 152.

Figure 154.

Charge pump lower valve plate

31. Inspect charge pump inner and outer rotor (47) for

damage or excess wear. If inner or outer rotor are

scratched or galled, the gears must be replaced as a set.

Figure 152.

See Fig. 155.

Inspecting charge pump upper valve plate

Figure 155.

Inspecting outer rotor

Figure 153.

Rotate one gear within the other to check for free action.

Inspecting charge pump eccentric

If action seems stiff in a particular area, use a hard

If wear patterns cannot be felt. inspect valve plates

Arkansas stone and lightly touch up the gear edges. Re-

for nicks and burrs. Rub flat faces and the outside edge

check for free rotation.

with 500 grit emery paper on a lap

32. Position key (46) in shaft keyway. Install charge

102