TM 5-3895-356-14&P

TYPE III HYDRAULIC MOTOR

TYPE II HYDRAULIC MOTOR

HYDRAULIC MOTOR RELIEF

PRESSURE ADJUSTMENT

If pump and motor case dram

rate and air leaks are not a problem,

proceed to adjust hydraulic motor

relief pressure as outlined below

First, determine which of the

three types of hydrostatic motor has

been installed on your distributor

Then adjust pressure as indicated for

the particular motor involved

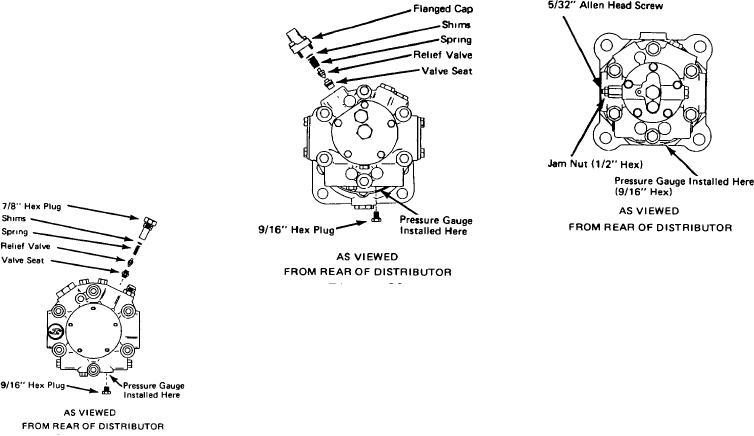

TYPE I HYDRAULIC MOTOR

Figure 34

1. Loosen jam nut (1/2" hex)

and turn 5/32" Allen head screw m so

Figure 33

as to increase pressure A pressure

increase of 800 PSI per turn may be

1. Remove flanged cup casting

expected

located as shown on rear of hydraulic

2. Increase

pressure

to

motor This contains relief valve,

recommended level of 4000 to 4500

spring and shims

P S.I

2. Add required number of

3. Retighten jam nut while

shims so as to increase pressure to

holding screw.

recommended level of 4000 to 4500

Figure 32

4. Remove gauge and replace

P S.I Pressure may be increased at

9/16" hex plug

1. Of the two 7/8" plugs, located

the rate of 50

PSI

per one

on top of the motor, remove the one

thousandth (001") of shim.

CAUTION

nearest the universal coupling

3. Before replacing apply dab of

between motor and Etnyre asphalt

petroleum jelly or vaseline on

1. Throughout

the

entire

pump.

assembly to prevent RELIEF valve

operation, hands , parts, tools and

2. Exercise care m removal of

and spring from dropping out.

immediate area must be kept clean

this plug, spring, shims and relief

4. Re-check

pressure

and

Introduction of foreign material into

valve Should valve and spring fall

make additional adjustments If

the system may damage or hinder its

into discharge port, they may be

necessary

operation.

retrieved with a pencil magnet.

5. Remove gauge and replace

3. Add required number of

9/16" plug.

2. Do not operate the hydraulic

shims so as to increase pressure to

motor at maximum by-pass pressure

recommended level of 4000 to 4500

for extended periods of time since

P S I Pressure may be increased at

this will cause overheating of

the rate of 50 P I per one

hydraulic oil and result in system

thousandth ( 001") of shim.

damage

4. Before replacing plug, apply

a dab of petroleum jelly or vaseline

3. Recommended

relief

on end of tube to prevent valve,

pressure 4000 to 4500 P.S.I

spring and shims from dropping out

5. Re-check

pressure

and

4. For accessibility, removal of

make additional adjustments if

bar box or center platform is

necessary

recommended.

6. Remove gauge and replace

9/16" plug

26