TM 5-3895-356-14&P

If the roller bearing (50) is removed from the cover, then

EXCEPTION

the inner race must also be replaced, as they are a

matched set.

On older units, nuts and lock washers are removed from

studs. Do not remove studs from housing unless

NOTE:

damage is evident.

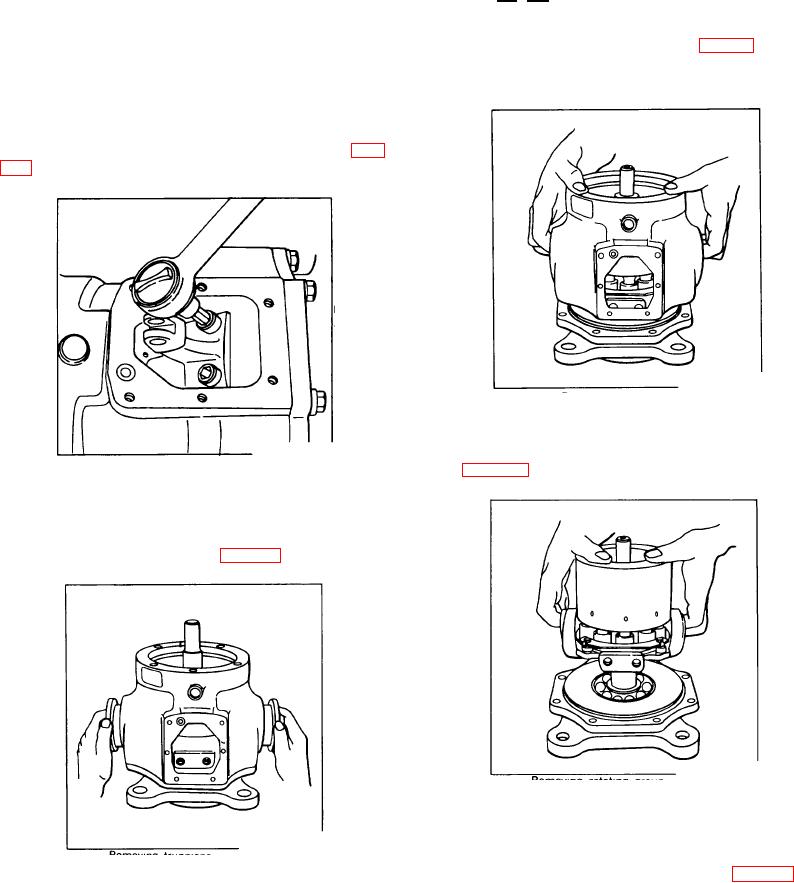

10. Remove housing (8) as shown in Fig. 14 by lifting

Control assembly must be removed

housing straight up until all internal parts are cleared. Do

from pump at this point to proceed to

not disturb internal parts during this operation.

Step 7.

7. Using an Allen wrench, remove Allen socket head

cap screws (28) from the cam control lever assembly

(35). Remove lever assembly from cam (12). See Fig.

Figure 117.

Removing housing

11. Lift off rotating group consisting of parts (12, 18,

19, 20, 34, 37, 51, 52, 53, 54, ) from mounting flange (2).

See Fig. 118.

Figure 115.

Removing cam lever arm

8. From the sides of the housing (8) remove hex bolts

(5) and lock washers (6). Pull out trunnions (7) and

thrust washers (27) as shown in Fig. 116.

Figure 118.

Removing rotating group

12. At the factory each block is marked to indicate

cylinder bore number one., Mark piston number one with

felt pen or a similar devise as a convenient method of

Figure 116.

preserving the bore/piston relationship. See Fig. 119.

Removing trunnions

Remove cylinder block (37) by lifting straight up until

9. Remove hex bolts (3) and lock washers (4) from

piston assemblies are cleared.

using (8).

92