TM 5-3895-356-14&P

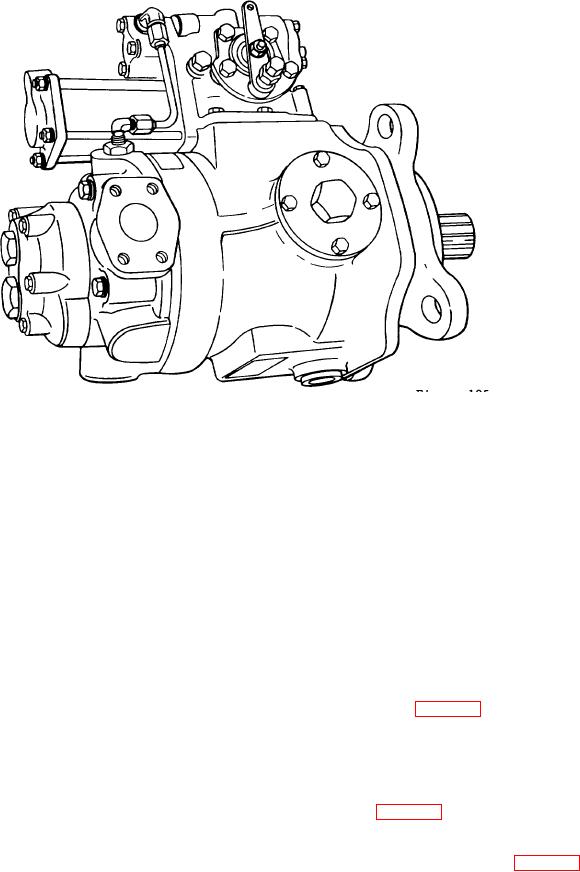

PUMP OVERHAUL - MODEL 45

Figure 105.

This section contains an illustrated, step-by-step

square block of wood, 4" thick with a 2" round center

procedure for the complete disassembly and reassembly

hole, may be used as a platform upon which the pump

of the Dynapower Phase III, Model 45 and Model 60

may be positioned. A similar size hole in a work bench

pumps. Additional information for servicing Dynapower

surface may be utilized as can the corrugated cardboard

units no longer in production is included where

spacer packed at the end of a new Dynapower pump.

applicable.

C. If complete disassembly is anticipated, the control

Service procedures for the Model 45 and Model 60 units

assembly must be removed.

are alike in all respects. Only when replacing the cover,

block, pistons, return plate, mounting flange and cam

D. When performing minor service work, do not remove

stop is it necessary that the displacement of the unit be

bearings, dowel pins or cylinder block components

known. Photographs are included, where necessary, to

unless they exhibit signs of galling, scratches, or

establish the identity of the units being serviced.

excessive wear.

On major overhaul, replace all

Individual parts and numbers are available from your

bearings, seals, gaskets, tablocks (16), wear plates (20)

Dynapower representative.

and bronze crescent clips (14).

ALL PART NUMBERS IN PARENTHESIS FOLLOWING

E. Upon completion of service operations, be sure to

THE PART NAMES REFER TO THE INDIVIDUAL

follow instructions in page 130 for restarting the system.

PARTS AS IDENTIFIED IN FIGURE 236 EXCEPT AS

NOTED.

PUMP DISASSEMBLY

GENERAL INSTRUCTIONS

1. Place the pump in a shaft down position. Remove

A. Dynapower parts and work area must be kept

hex bolts (11) and lock washers (6). Lift off charge pump

absolutely clean at all times. The Dynapower unit must

cover (10) See Fig. 236.

be cleaned externally with a commercial solvent or

steam and dried with compressed air before the unit is

Remove .charge pump inlet port plate (45), shim

removed from the application.

gasket(s) (43) and O-ring (44). See Fig. 236.

B. Most service operations are carried out with the

pump in a shaft down position. A seven inch

89