Malfunction

Probable Cause

Hot to Determine

Corrective Action

Page

Steps

3. Excessive noise, cavit- Oil

Check oil for excessive viscosity

Replace as necessary

ation and internal damage

Continued

Check for water in oil

Replace as necessary - check heat

exchanger for possible leaks

Check case drain line for steel

Unit probably beyond field repair.

or brass particles

Remove and overhaul

Air in oil

Check inlet line for leaks

Tighten fittings or replace as

necessary

Check oil level in reservoir

Add oil as necessary

Maintain oil level above level of

return line

4. Overheating

Excessive internal wear

Check case drain. Volume should

Unit probably beyond field repair.

not exceed GPM per 1000 psi

Remove and overhaul.

working pressure per unit

Relief valves

Check relief valve setting

Set relief valves a minimum of 500 129

C4

psi above normal operating pressure or

500 psi above override control setting,

whichever is highest

5. Loss of Pressure

Relief valve malfunction

Check pressure with motor stalled

Adjust relief valve or replace as

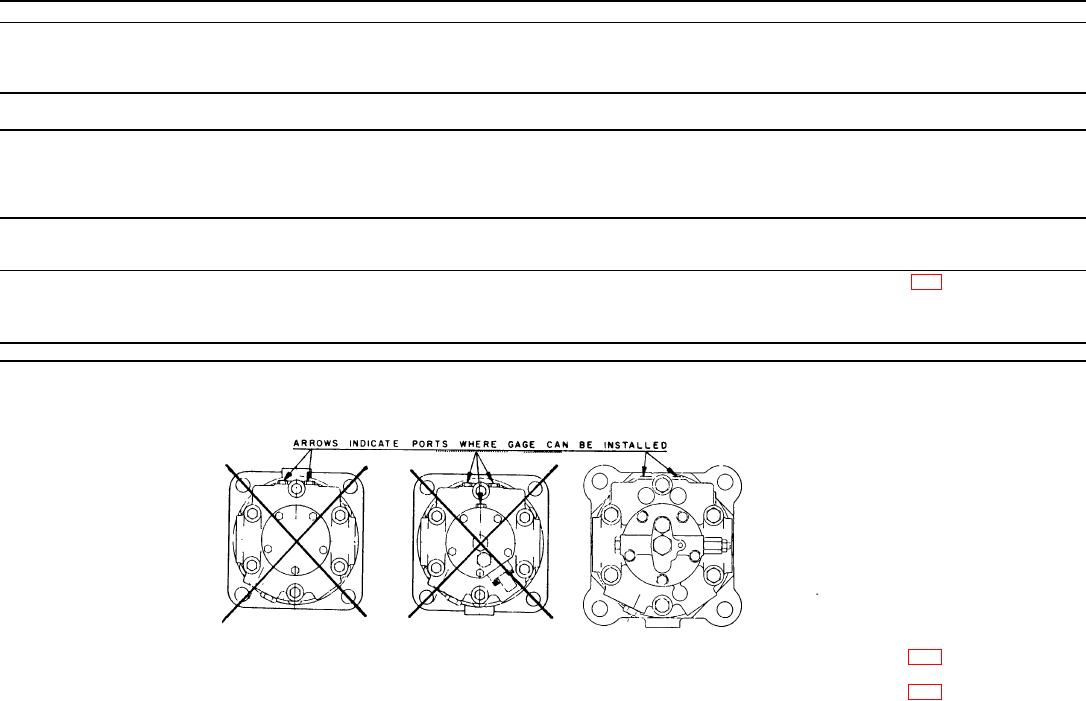

at points indicated below. Pres-

necessary

sure should be within 100 psi of

value on name plate

Figure 103.

Remove high pressure relief valve

Replace or adjust as necessary

C-2

assembly and check for cut O-Rings

Check small hole in high pressure

If plugged, clean or replace as

C-2

relief valve for burrs or contamination

necessary

87