(in comparison to properly tightened frames) to deform the

spring hangers. If spring should be deformed, straighten or

replace before attaching new screed bottom. Loose or

deformed spring hangers can be a cause for poor screed

control.

(2) Install crown gauge pointers No. 3.

(3) Position new screed bottom so that studs align with

holes

in

the

screed

frame.

Then,

lower

screed unit onto Screed Bottom and fasten with

GRIPCO

Center

Lock

Corrosion

Resist

Nuts.

Before

tightening

GRIPCO

Nuts,

push

screed

bottom as far forward as possible. Then, tighten

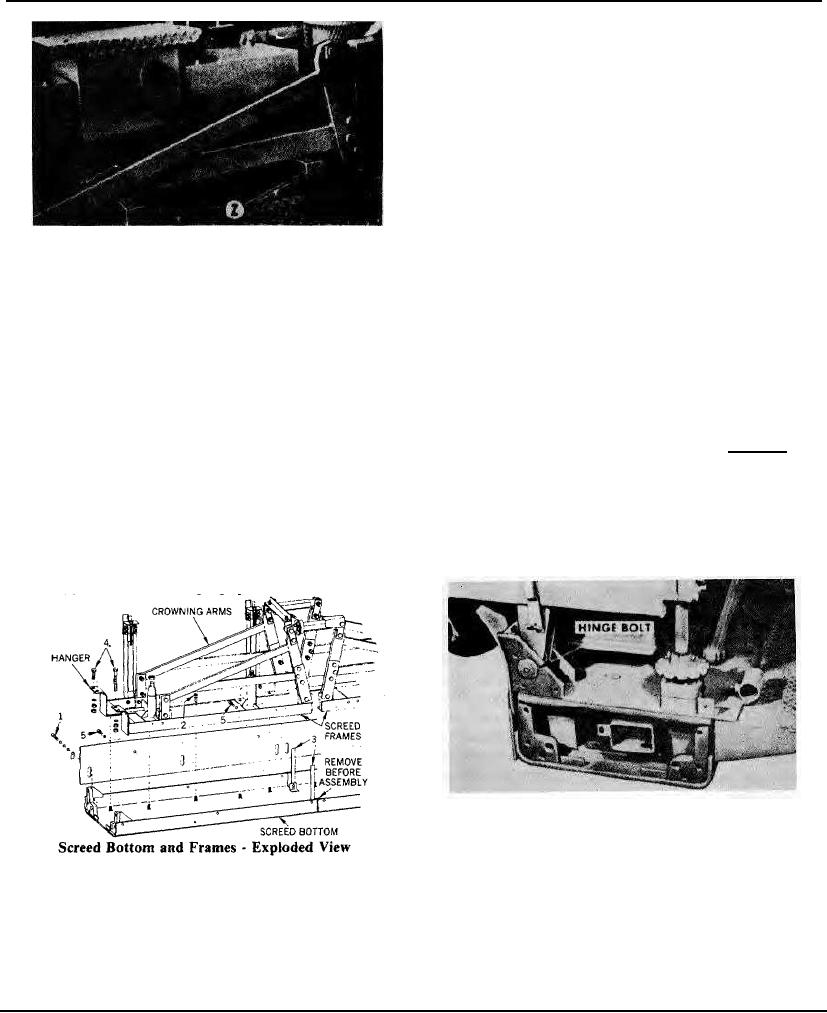

Supporting Crowning Arms For

Screed Bottom fastening nuts to 90 Ft./lbs. torque.

Screed Bottom Removal

(4) Install strike-offs to screed bottom. Check to

Figure 32

make sure that strike-offs are not gouging or locking

against mold board. Also check for excessive

SCREED UNIT

clearance between strike-offs and mold board. If

clearance is excessive, tack weld a 1/4" rod of

Removing Quick-Change Screed Bottom (Refer to

required length to top of strike-offs. Failure to

Figure 33)

properly seal this area will allow asphalt to seep into

1) Adjust screed crown to "O" crown. Then

screed bottom making the change in the screed

place wood blocks as shown in Figure 32, Item "Z"

bottom more time-consuming.

to support crowning mechanism. These blocks must

(5) Install walkway.

extend under both front and rear crowning arms

and on both right and left hand side of screed. This

CAUTION: If screed bottom is to be reversed the

will hold frame level and allow studs to align with

inside of screed must be thoroughly clean, to insure

support frame bolts.

proper seating of frame to screed bottom, and

(2) Remove walk-way

consequently obtain the maximum tightness with

(3) Remove Strike-off bolts No. 1 and No. 5.

fastening studs and nuts.

(4) Remove Screed bottom GRIPCO Nuts No.

2. (5/8" GRIPCO Corrosion Resist - Center Lock).

(5) Remove crown guage pointers No. 3

Location Of Screed Hinge Bolt

Figure 34

SCREED BOLTS

Screed Bottom and Frames-Exploded View

The bolts which attach the screed bottom to the

Figure 33

frame and the frame tc the pull arms must be kept

tight at all times. When bolts become loose and the

Install Screed Bottom as follows:

screed bottom is no longer rigidly held, waves may

(1) Check tightness of bolts No. 4 that fasten frame

appear in the finished mat. Check all screed bolts

spring hangers to top frame. If screed frames are operated

frequently for tightness.

with loose fastening bolts, it will take only one-half the load

In the event that the hinge bolts (Figure 34)

Page 114