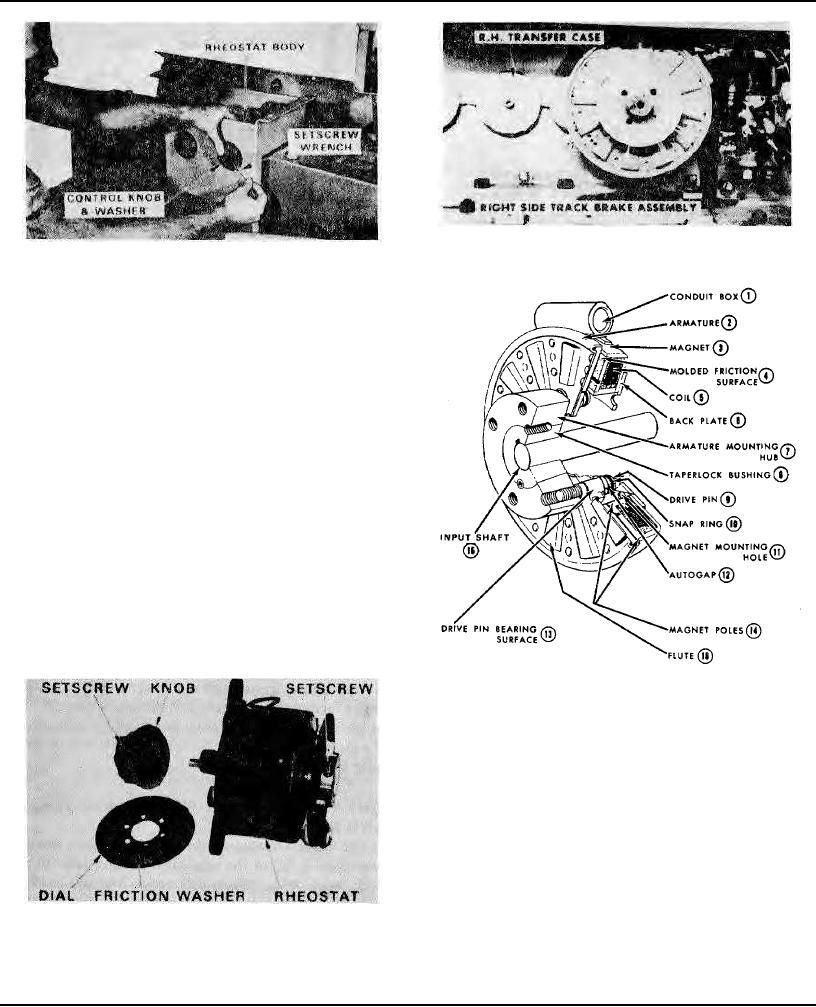

Electric Brake For Right Hand Crawler Track

Tightening Vibrator Control Knob

Figure 40

Figure 38

VIBRATOR CONTROL KNOB

INSTALLATION

The black plastic knob which adjusts the intensity of

vibration for each vibrator, is equipped with a

neporene friction washer to prevent vibration from

rotating the knob during the paving operation.

To correctly assemble a knob to a transformer,

remove walkway cover and loosen the allen

setscrews in knob, and push knob with washer

tightly against dial on control box, while holding

opposite end of shaft. (See Figure 38) Lock Allen

setscrews tightly to the shaft. Rotate knob to check

for sufficient resistance to insure that the knob will

remain in any desired position.

IMPORTANT! If the shaft "bottoms" in control

knob before the required friction is obtained

between washer and dial, it will be necessary to

loosen the setscrews at- the back of the rheostat

inside the housing, and to move the shaft farther

into the rheostat to reduce the amount of shaft in the

knob. Relock setscrews

Cut-away Showing Electric Brake Components

Figure 41

ELECTRICALLY RELEASED BRAKES

The two electrically released brake assemblies are

of the dry friction disc type. Braking force is applied

by permanent magnets in the stationary ring which

attracts the movable disc attached to the gear

reducer shaft. The brake is released when electric

current is passed through a coil surrounding the

permanent magnets to neutralize their magnetic

fields. The movable disc on the shaft is moved away from

the stationary ring by small coil springs and is

then free to revolve. Electric current for brake

Vibrator Rheostat, Dial And Knob

operation is controlled by toggle switch from the

Figure 39

operator's console.

(Continued)

Page 117