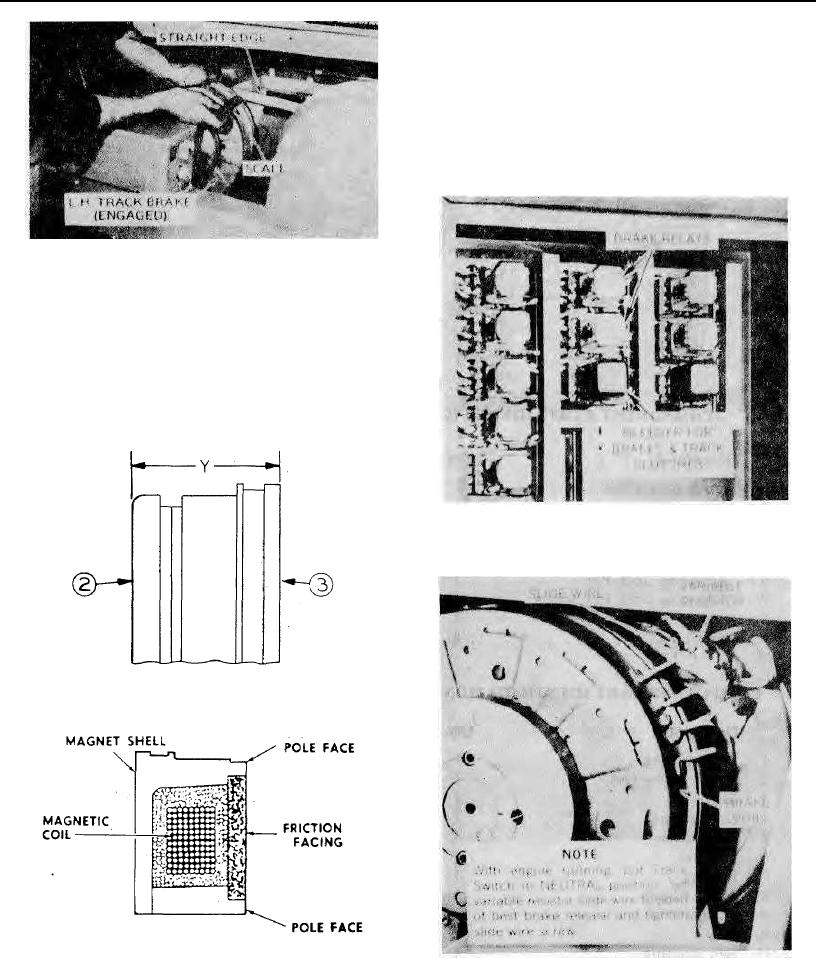

BRAKE ELECTRICAL MODULE

The electrically released brake system includes a

plug-in relay and E.M.F. bleeder module located in

the main electric panel. The relay is for ON-OFF

power application by remote control switch. The

bleeder is for electromotive force dissipation when

the power contacts open. (See Figure 47)

Adjustment of the brake release point is covered

by Figure 48.

Method Of Measuring Wear Of Electric Brake

Figure 44

The simple and accurate wear check is made by

measuring the combined thickness of Magnet (3)

and Armature (2) when the armature is pressed tight

against the magnet. (See Figures 44 & 45) When

both parts are new, dimension Y will be 3-1/16".

When completely worn-out, Y will be 2-3/4". Be

sure that the console switch is at, BRAKE so that the

armature is held tight against the rotor when the

measurement is taken.

Location Of Brake Relays & E.M.F. Bleeder

Figure 47

Side View Brake Showing Wear-check Dimension

Figure 45

Cross-section Thru Electric Brake Magnet Assembly

Figure 46

Variable Resistor For Brake Release Adjustment

Figure 48

Page 119