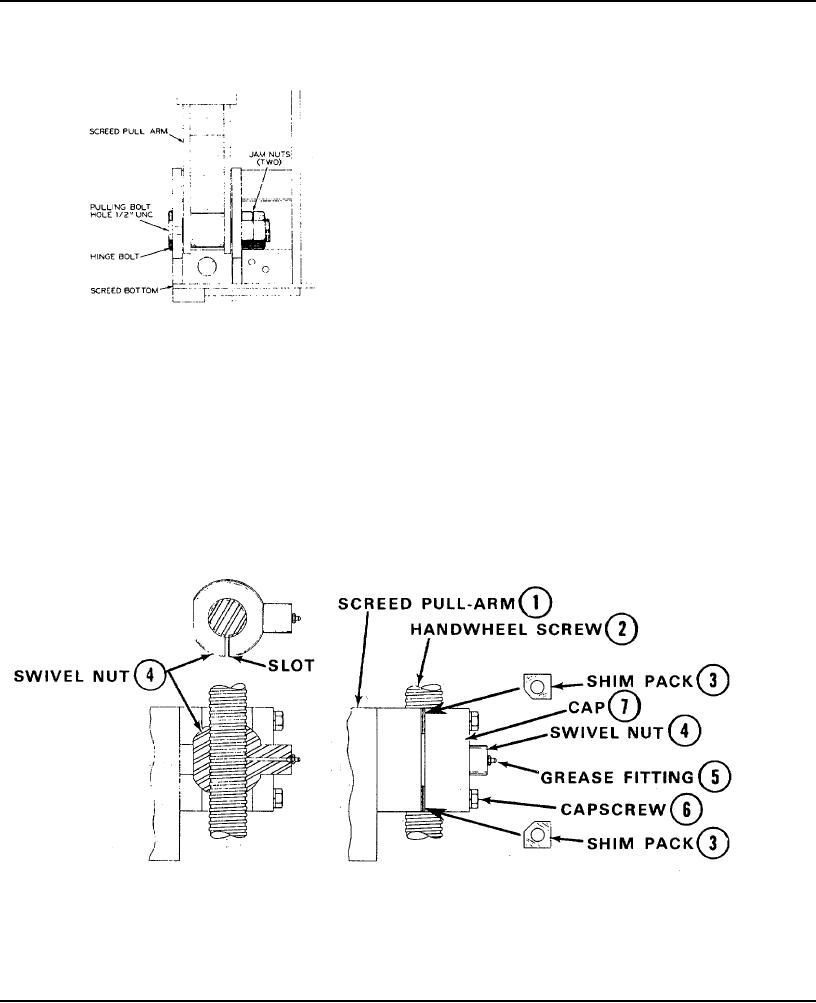

become worn, they should be replaced so that no Swivel Nut Adjustment (Refer to Figure 36)

play develops at that critical point to produce a

The pull arm couplings are slotted Swivel Nuts (4)

waviness in the mat. Hinge bolts are made with "1/2' which utilize the ball and socket principle. The

UNC pulling bolt hole to aid in bolt removal (See Figure 35). socket is made up of the pull arm (1) and Cap (7)

with four Shim Packs (3) used for adjustability.

Adjustment of the Shim Pack thickness changes the

amount of "squeeze" exerted on the slotted Swivel

Nut (4) and the corresponding tightness of fit

against the Screw (2) threads.

Whenever looseness is felt, first check the four

Capscrews (6) for tightness. If they are tight, remove

them and Cap (7). Remove an equal amount of

Shim Pack (3) stock from the four packs and reassemble.

Replace worn Swivel Nuts (4) when adjustment no

longer corrects looseness.

Detailed Of Screed Hinge Bolt In-place

Ball Coupling (Refer to Figure 37)

Figure 35).

Normally handwheel screw looseness will be due

to clearance at the two Swivel Nuts (4). It can,

HANDWHEEL SCREW MAINTENANCE

however, be due to badly worn ball bearings at the

Both handwheel screw assemblies should be kept

lower end coupling point. If it is determined that the

in good operating condition so that they hold the

screed couplings are at fault, refer to following

screed rigidly at the desired setting. Looseness at the

paragraphs for replacement instructions.

two pull arm coupling points or at the two screed

coupling points will allow free up and down

movement of the screed and corresponding waves in

the mat surface. There must never be more than

three notches of play (free handwheel movement,

without affect on the screed).

Detail Of Screed Handwheel Screw And Pull-arm Swivel Nut Coupling

Figure 36

Page 115