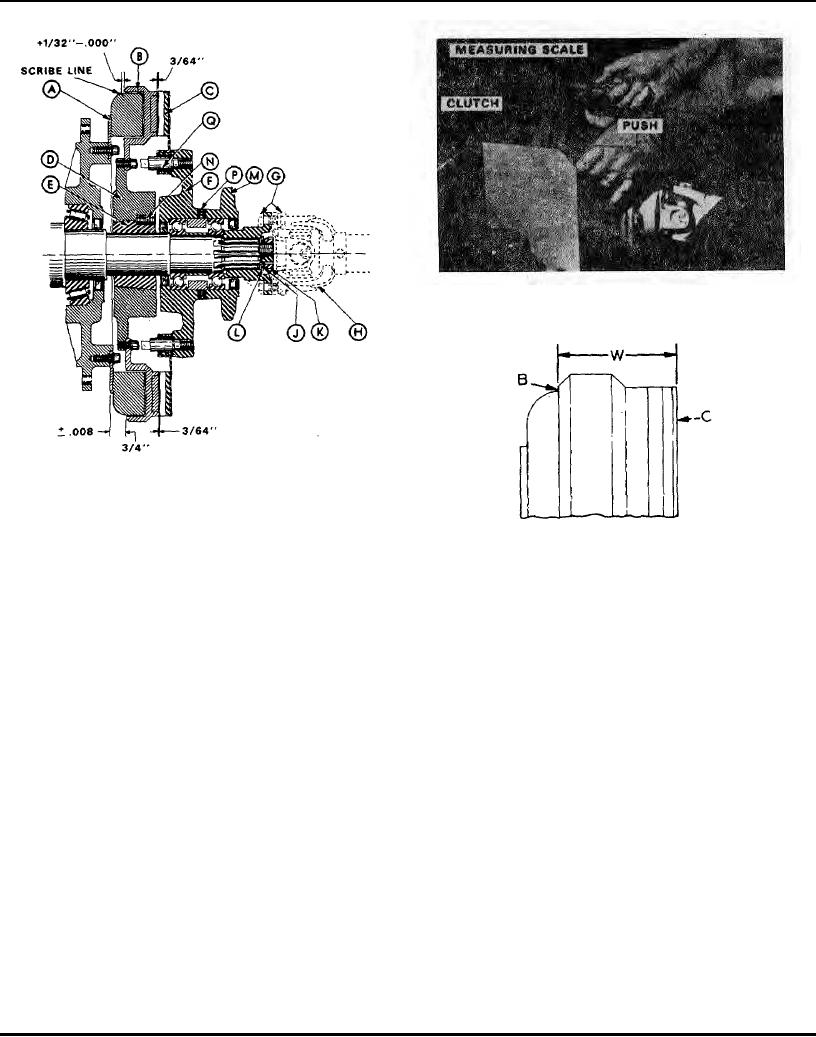

Method Of Measuring Wear Of Electric Clutch

Figure 30

Cross-section Thru Electric Feed Clutch

(Travel clutch identical except for hub)

Figure 29

Side View Of Clutch Showing Wear-check Dimensions

Figure 31

IMPORTANT! Use a machinists dial gauge on

Travel Clutch Adjustment

the face of Rotor "B" to be sure that surface is

running true as it is turned through 360 of rotation.

Refer to Feed Clutch adjustment details in preceding

This will assure 100% contact of the friction face

paragraphs. The travel clutch is identical except for the hub

with the friction face of Armature "C". If the dial

area. Use Figure 29.

gauge indicates more than .010" total variation,

Bushing "E" must be tapped on the side that will

When To Replace Worn Out Armature & Rotor

true-up the Rotor, and the set screws re-tightened to

hold the alignment. If the Rotor is not adjusted in

The clutch armature-rotor set is completely worn-out when

this way and fails to run true, serious clutch slippage

9/32" of the combined friction faces has been worn away.

will result.

When this occurs the two parts must be replaced in order to

CAUTION: DO NOT POUND ON POLES OF

avoid a breakdown at a critical time.

ROTOR.

(5) When clutch is assembled and drive is in

The simple and accurate wear check is made by measuring

place, check .046" opening between Armature "C"

the combined thickness of the Rotor "B" and Armature "C",

Rotor "B". Make adjustment if necessary.

when the movable armature is pressed tight against the rotor.

(6) For other alignment checks, refer to

(See Figures 30 and 31) When both parts are new, dimension

separate clutch manual.

"W" will be 2 1/8". When completely worn-out, "W" will be

NOTE: Care should be taken to keep clutch

1 27/32". Be sure that the armature is held tight against the

clean when assembling.

rotor when the measurement is taken.

Page 113