TM 5-3895-373-34

2.68

REPLACE AUGER BEARING UNITS, SHAFT, AND SPROCKET WHEEL - Continued

C.

INSPECT.

1.

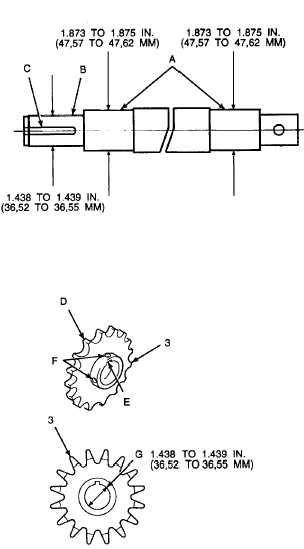

INSPECT SHAFT.

a.

Visually inspect shaft for straightness. Roll shaft

across a clean level surface. Check for out-of-

roundness. Replace shaft if bent or out-of-

round.

b.

Inspect bearing surfaces A on shaft for scoring

and gouging. Replace shaft if scoring or

gouging is detected.

c.

Use outside micrometer and measure bearing

surface diameters (A) on shaft. Bearing surface

diameters on shaft should measure between

1.873 and 1.875 in. (47, 57 and 47, 62 mm). If

bearing surface diameters on shaft measure less

than 1.873 in. (47, 57 mm), replace shaft.

d.

Inspect sprocket wheel surface B on shaft for

scoring or gouging. Replace shaft if scoring or

gouging is detected.

e.

Use outside micrometer and measure sprocket

wheel surface (B) on shaft for wear. Sprocket

wheel surface diameter on shaft should measure

between 1.438 and 1.439 in. (36, 52 and 36, 55

mm). If sprocket wheel surface diameter on

shaft is less than 1.438 in. (36, 52 mm), replace

shaft.

f.

Inspect shaft keyway C for damage. Replace

shaft if keyway is visibly damaged.

2.

INSPECT BEARINGS.

a.

Spin bearing by hand.

b.

If bearing does not spin freely, or radial free play

is detected, discard and replace ball bearing unit.

3.

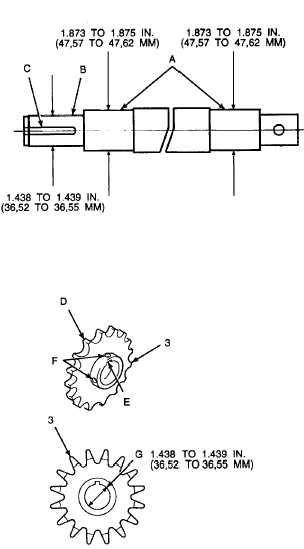

INSPECT SPROCKET WHEEL.

a.

Inspect sprocket wheel (3) for broken, missing,

and worn teeth D. Replace damaged sprocket

wheel.

b.

Inspect sprocket wheel (3) keyway E for worn or

broken edges. Replace sprocket wheel if

keyway is worn or damaged.

c.

Inspect sprocket wheel (3) for stripped or

damaged set screw threads F. Replace

sprocket

wheel

if

set

screw

threads

are

damaged.

d.

Using a slide caliper measure the inside

diameter G of sprocket wheel (3). The inside

diameter should measure between 1.438 and

1.439 in. (36,52 and 36,55 mm). If the inside

diameter is more than 1.439 in. (36,55 mm),

replace sprocket wheel.

GO TO NEXT PAGE

2-962