TM 5-3895-373-34

2.64

REPLACE/REPAIR CONVEYOR DRIVE SHAFT, BEARING UNITS, AND SPROCKETWHEELS- Continued.

D.

INSTALL - Continued.

5.

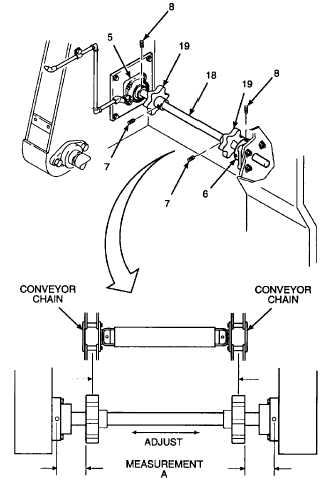

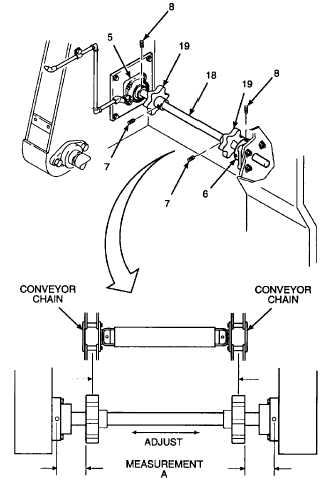

ALIGN DRIVE SHAFT AND SPROCKET

WHEELS.

NOTE

Before setting sprocket wheel width

distance,

ensure

drive

shaft

is

oriented to allow proper adjustment

of sprocket wheel per step 6.

a.

Measure the width of the conveyor chain from

center of the chain links on the left and right

side. Set distance between sprocket wheels

(19) measuring from the center of the sprocket

wheel so it is the same as chain width. Secure

sprocket wheels in place with set screws (7), but

do not tighten at this time. Further adjustments

may have to be made during conveyor chain

assembly installation.

b.

Adjust drive shaft (18) so there is equal distance

between the outside edges of sprocket wheels

(19) and center of lubrication line hole in

bearings, measurement A, on inner and outer

bearing units (5 and 6).

WARNING

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

c.

Remove set screws (8) and apply thread locking

compound to threads.

d.

Install set screws (8) and tighten to 19 lb-ft (26

N.m) using hex head driver socket.

GO TO NEXT PAGE

2-882