TM 5-3895-373-34

2.64

REPLACE/REPAIR CONVEYOR DRIVE SHAFT, BEARING UNITS, AND SPROCKETWHEELS -Continued. -

C.

INSPECT - Continued.

2.

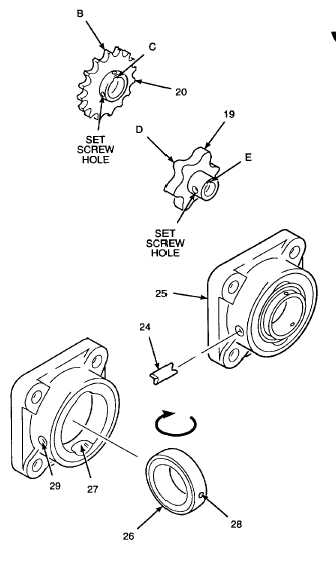

INSPECT SPROCKET WHEEL TEETH AND

KEYWAY.

a.

Inspect sprocket wheel (20) for broken, missing,

and worn teeth B. Replace damaged sprocket

wheel.

b.

Inspect sprocket wheel keyway C for worn or

broken edges. Replace sprocket wheel (20) if

keyways are worn or broken.

c.

Inspect threads of set screw holes. If threads

are damaged, replace sprocket wheel (20).

3.

INSPECT

SPROCKET

WHEELS

FOR

DAMAGED TEETH AND KEYWAYS.

a.

Inspect sprocket wheels (19) for sharp, broken,

or missing teeth D. Replace defective sprocket

wheels.

b.

Inspect sprocket wheel keyway E for worn or

broken edges. Replace sprocket wheel (19)

having worn or broken edges.

c.

Inspect threads of set screw holes. If threads

are damaged, replace sprocket wheel (19).

4.

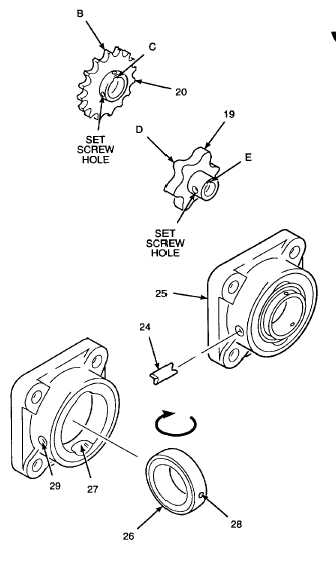

INSPECT BEARINGS (26) FOR LOOSENESS

OR RADIAL FREE PLAY. REPLACE IF

LOOSENESS OR RADIAL FREE PLAY IS

PRESENT.

D.

INSTALL.

1.

INSTALL BEARING INTO BEARING HOUSING.

a.

Hold bearing (26) perpendicular to bearing

housing (25) and align with housing slots (27).

b.

Push bearing (26) into housing slots (27). Stop

when the bearing is halfway inserted.

NOTE

Orient bearing to ensure lock pin hole

alignment with bearing housing lock

pin hole.

c.

Rotate bearing (26) until parallel with bearing

housing (25).

d.

Align bearing lock pin hole (28) with bearing

housing lock pin hole (29).

e.

Insert lock pin (24) through lock pin holes (28

and 29).

f.

Push lock pin (24) below the surface of bearing

housing (25).

GO TO NEXT PAGE

2-878