TM 5-3895-373-34

2.43

REPLACE/REPAIR AUXILIARY VIBRATION PUMP - Continued

E.

ASSEMBLE - Continued.

3.

ASSEMBLE AUXILIARY VIBRATION PUMP.

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to the

eyes, skin, and respiratory system.

Avoid

prolonged

exposure.

Eye

protection and rubber gloves must be

worn when working with hydraulic oil.

Hydraulic pump components must be

thoroughly

clean

upon

assembly.

Always

flush

internal

component

surfaces with clean hydraulic oil to wash

away fine contaminant particles. Failure

to properly clean and thoroughly flush

components prior to assembly may

result in equipment damage or failure.

a.

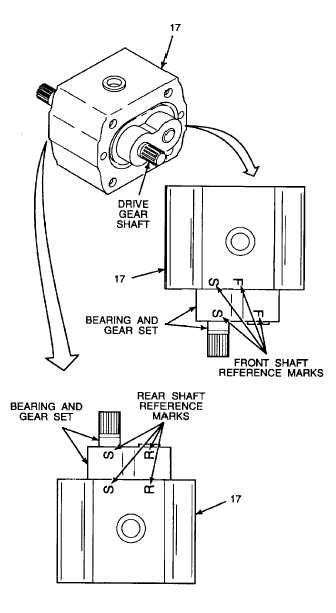

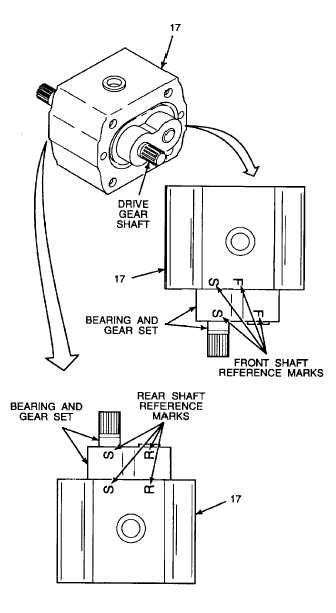

Immerse pump housing (17) in clean hydraulic

oil. Drain away excess oil. Wipe off external

surface of housing with lint-free cleaning cloths.

Set housing on clean work surface, with F and S

reference marks facing up.

b.

Dip assembled bearing and gear set into

hydraulic oil.

Drain away excess oil.

c.

With long end of drive gear shaft in line with S

marked port, insert assembled bearing and gear

set into pump housing (17). Wipe away excess

oil seepage with lint-free cleaning cloths. Ensure

that F and S, and R and S, reference marks are

aligned.

GO TO NEXT PAGE

2-596