TM 5-3895-373-34

2.43

REPLACE/REPAIR AUXILIARY VIBRATION PUMP - Continued

D.

INSPECT.

1.

INSPECT PUMP HOUSING.

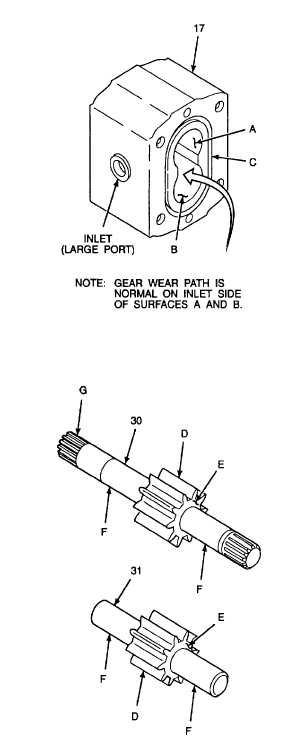

NOTE

Gear tracking on inlet (large port) side of

pump housing will create a stepped wear

path. A uniform wear path is normal and

should not be considered reason for

rejecting pump housing.

a.

Visually inspect pump housing (17) interior surfaces A

and B for scoring and grooving of gear paths.

b.

Replace auxiliary vibration pump if scoring or grooves

are found in gear paths.

c.

Inspect seal grooves C on both ends of pump housing

for sharp edges caused by scratches, nicks, or burrs.

Remove sharp edges with emery cloth.

d.

If scratches or nicks cause leakage paths more than

halfway across seal groove, replace auxiliary vibration

pump.

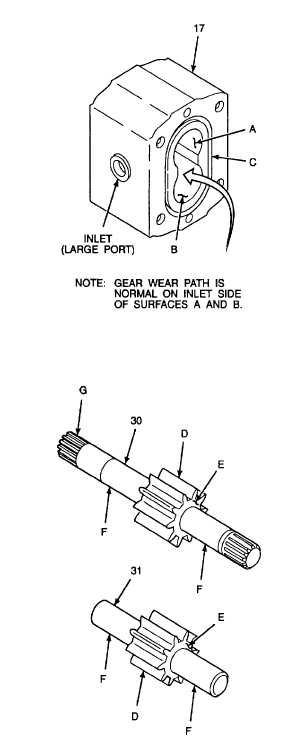

2.

INSPECT DRIVE GEARS AND IDLER GEARS.

Drive gear and idler gear teeth are highly

polished. Avoid contact with bare fingers.

Skin oils can erode polished surfaces.

Wear clean cotton or polyester gloves

when handling gears.

a.

Visually inspect drive gear (30) and idler gear (31),

teeth surfaces D and gear faces E, for nicks, chips,

scoring, or discoloration.

b.

Replace drive and idler gears (30 and 31) if any

damage is found on surfaces D or E, or if scoring or

burnishing is found on surfaces F.

c.

Remove small burrs or scratches from surfaces with

emery cloth. Clean gears after polishing. Refer to

cleaning procedure.

d.

Inspect splines G for nicks, chipping, and wear

indicated by rounding of spline teeth. If spline

damage is indicated, replace both the drive and idler

gears (30 and 31).

GO TO NEXT PAGE ’

2-592