TM 5-3895-373-34

E.

ASSEMBLE - Continued.

m.

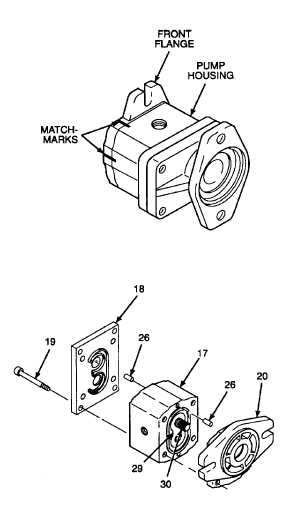

Carefully pick up front flange and rotate seal

face to vertical position. Align matchmarks on

flange perimeter with matchmarks on pump

housing.

n.

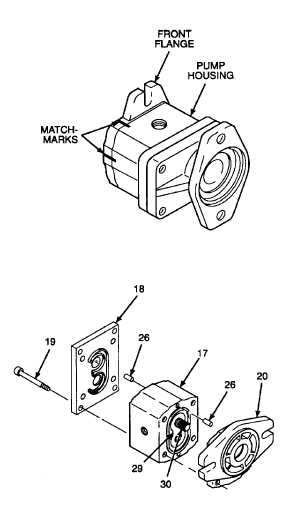

Carefully support installed bearing unit (29) at

rear of pump housing (17) with one hand, and

slide front flange (20) squarely over long end

shaft of drive gear (30) with the other hand.

o.

Line up installed guide pins (26) with guide pin

holes in front flange (20). Fully seat face of front

flange against face of pump housing (17).

p.

Carefully pick up rear cover (18) and rotate seal

face to vertical position. Align matchmarks and

line up guide pin holes in rear cover with

installed guide pins (26). Fully seat face of rear

cover against face of pump housing (17).

q.

With both ends of auxiliary vibration pump

clamped firmly in one hand, install and finger

tighten socket head cap screws (19).

Do not clamp vise jaws against pump

housing. Clamping against pump

housing walls can deform internal

cavities

and

cause

permanent

damage to the auxiliary vibration

pump.

r.

Clamp rear cover (18) in vise jaw caps of bench

vise to secure auxiliary vibration pump. Evenly

tighten

socket

head

cap

screws

(19)

in

increments, using a diagonal tightening pattern.

Tighten cap screws to 39 lb-ft (53 N•m).

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to

the

skin,

eyes,

and

respiratory

system. Avoid prolonged exposure.

Eye protection and rubber gloves

must be worn when working with

hydraulic oil.

s. Pour a small amount of clean hydraulic oil into

inlet port of auxiliary vibration pump. Place

pump on machinery wiping towel.

GO TO NEXT PAGE

2-599