TM 5-3895-373-34

2.43

REPLACE/REPAIR AUXILIARY VIBRATION PUMP - Continued

D.

INSPECT - Continued.

4.

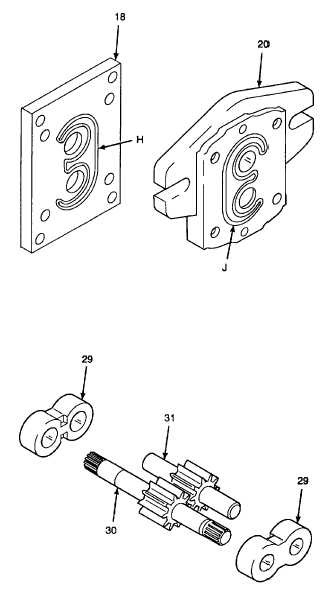

INSPECT REAR COVER AND FRONT FLANGE.

a.

Inspect seal grooves H and J in rear cover (18)

and front flange (20) for sharp edges caused by

scratches, nicks, or burrs. Remove sharp

edges with emery cloth.

b.

If scratches or nicks cause leakage paths more

than halfway across seal groove H or J, replace

damaged component.

E.

ASSEMBLE.

1.

ASSEMBLE AUXILIARY VIBRATION PUMP.

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to

the

skin,

eyes,

and

respiratory

system. Avoid prolonged exposure.

Eye protection and rubber gloves

must be worn when working with

hydraulic oil.

Drive and idler gear teeth are highly

polished. Avoid contact with bare

fingers. Skin oils can erode polished

surfaces. Wear clean cotton or

polyester

gloves

when

handling

gears.

a.

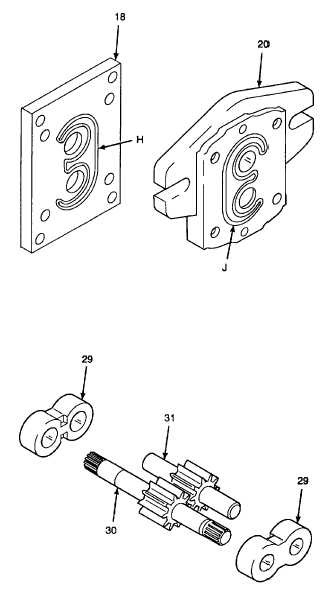

Lubricate bearing units (29), drive gear (30),

and idler gear (31) with clean hydraulic oil.

Slotted side of bearing units must be

installed

against

gear

faces.

Improper installation of bearing units

will cause auxiliary vibration pump to

fail.

NOTE

If installing new gears, disregard

instructions for matchmarks. New

gears are not matchmarked.

b.

Install matchmarked idler gear (31) into F

marked idler side of bearing unit (29).

GO TO NEXT PAGE

2-594