TM 5-3895-373-34

2.24.

REPLACE/REPAIR TRACK IDLER ROLLER ASSEMBLY- Continued

D.

ASSEMBLE - Continued.

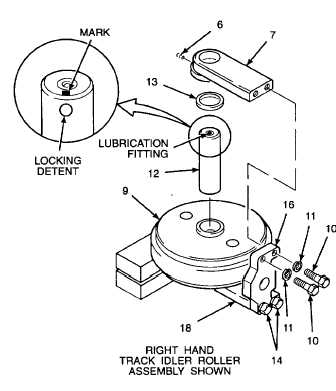

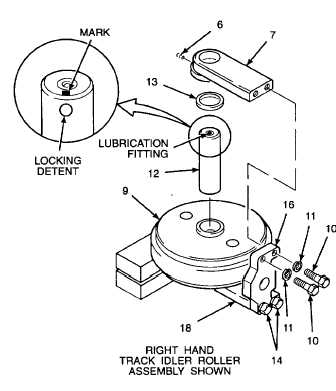

NOTE

The lubrication fitting on the shaft must

be pointing to the outside of the paving

machine. When assembling the RH

track idler roller assembly, install the

shaft with the lubrication fitting up.

When assembling the LH track idler

roller assembly, install the shaft with the

lubrication fitting down.

h.

Place shaft (12) with the lubrication fitting up if

assembling the RH track idler roller assembly,

and

with

the

lubrication

fitting

down

if

assembling the LH track idler roller assembly.

i.

Use a marker to indicate location of set screw

(6) locking detents in shaft (12). Mark on the

top end of the shaft.

j.

Apply a thin coating of grease to shaft (12).

k.

Install shaft (12), with mark up, in bore of track

idler roller (9). Fully seat installed shaft in

mating bore of LH track slide (18). Line up the

marks on the shaft with the set screw hole on

the LH track slide.

l.

Press plain seal (13) in RH track slide (7).

Metallic side of plain seal seal must be fully

seated in RH track slide seal bore.

m.

Slide RH track slide (7) down onto shaft (12).

Line up mounting holes in RH track slide with

idler shaft bracket (16).

n.

Install lockwashers (11) onto hex head cap

screws (10).

Thread locking compound can cause

eye damage.

Wear

safety

goggles/glasses

when

using. Avoid contact with eyes. If

compound contacts eyes, flush eyes

with water and get immediate medical

attention.

o. Apply thread locking compound (Item 13,

Appendix B) to threads of hex head cap screws (10).

p.

Install lockwashers (11) and hex head cap

screws (10).

q.

Secure

track

idler

roller

assembly

to

workbench using a C-clamp.

r.

Tighten hex head cap screws (10 and 14) to

355 lb-ft (481 N•m) using socket wrench

adapter (Item 6, Appendix D).

s.

Remove C-clamp and cribbing from track idler

roller assembly.

t.

Apply thread locking compound (Item 14,

Appendix B) to threads of set screws (6).

Install set screws and tighten to 42 lb-ft (57

N.m) using hex head driver socket and socket

wrench adapter (Item 7, Appendix D). Ensure

set screws engage locking detents of shaft

(12).

GO TO NEXT PAGE

2-512