TM 5-3895-373-34

A.

REMOVE - Continued.

2.

REMOVE TRACK TENSIONING CYLINDER.

Cleaning solvent, P-D-680 is TOXIC and

flammable. Wear protective goggles

and gloves. Use only in a well ventilated

area. Avoid contact with skin, eyes, and

clothes, and do not breathe vapors.

Keep away from heat or flame. Never

smoke

when

using

solvent;

the

flashpoint of Type III cleaning solvent is

200°F (93,30C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using

cleaning solvent, immediately get fresh

air and medical attention. If solvent

contacts skin or clothes, flush with cold

water. If solvent contacts eyes, flush

eyes with water and get immediate

medical attention.

Thoroughly

clean

hydraulic

hoses,

tubes, and fittings before disconnecting.

Always plug or cap off disconnected

fittings

to

prevent

intrusion

of

contaminants. Failure to properly clean

and cap off connectors may result in

hydraulic system contamination and

equipment damage.

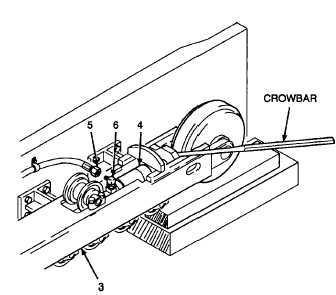

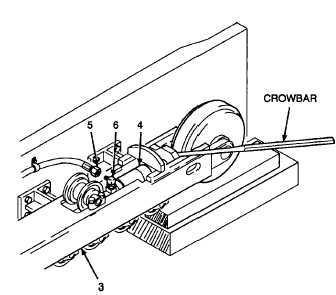

a.

Use cleaning brush and cleaning solvent to

clean all dust, dirt, and oil or grease residue

from hose (5) end and fitting at track

tensioning cylinder (4).

b.

Wipe off cleaned areas with a cleaning cloth.

Hydraulic oil can be moderately flammable and

can be an irritant to the skin, eyes, and

respiratory system. Avoid prolonged exposure.

Eye protection and rubber gloves must be worn

when working with hydraulic oil.

c.

Place machinery wiping towels

around elbow (6). Unscrew hose (5)

from elbow and drain hydraulic oil from

hose into drip pan. Plug hose and cap

elbow.

d.

Wipe up any spilled hydraulic oil with machinery

wiping towels. Dispose of hydraulic oil and

machinery wiping towels in accordance with

local procedures.

e.

Slide track tensioning cylinder forward to

dislodge rear end of track tensioning cylinder

from track frame (3). Remove track tensioning

cylinder

(4).

GO TO NEXT PAGE

2-515