TM 5-3895-373-34

2.37.

REPLACE TRACK TENSIONOING CYLINDER.

This task covers:

a.

Removal

b.

Install

INITIAL SETUP

Tools:

References:

General mechanic’s automotive tool kit

TM 5-3895-373-20

(Item 106, Appendix D)

TM 5-3895-373-24P

Cleaning brush (Item 12, Appendix D)

Crowbar (Item 35, Appendix D)

Equipment Condition:

Drip pan (Item 64, Appendix D)

Paving machine jacked and cribbed (for track maintenance) per

TM 5-3895-373-20.

Track chain assembly removed per 2.41.

Materials/Parts:

Cleaning cloth (Item 6, Appendix B)

Cleaning solvent (Item 31, Appendix B)

Hydraulic fitting sealant (Item 26, Appendix B)

Machinery wiping towels (Item 37, Appendix B)

Protective caps (Item 3, Appendix B)

Track tensioning cylinder

NOTE

There is a left hand and a right hand track tensioning

cylinder on the paving machine.

Remove the track chain assembly only from the side

being worked on. This procedure refers to replacement

of right hand track tensioning cylinder. Procedure is

identical for left hand track tensioning cylinder. Right

hand track tensioning cylinder is shown in this procedure.

A.

REMOVE.

1.

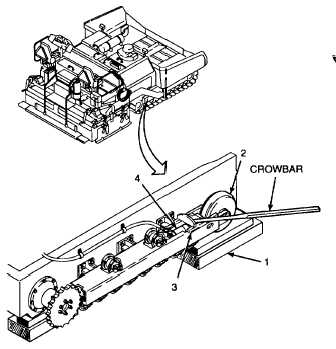

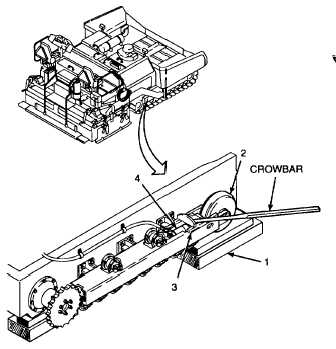

SEPARATE TRACK IDLER ROLLER ASSEMBLY

FROM TRACK TENSIONING CYLINDER.

The track idler roller assembly weighs

approximately 95 lbs (43 kg) and is

difficult to handle. Be careful when

moving track idler roller assembly from

track frame. Damage to equipment and

personnel

injury

may

result

from

unexpected movement.

a.

Stack cribbing (1) under and in front of track

idler roller assembly forward only as far as

needed to roller assembly (2).

b.

Carefully pry track idler roller assembly (2)

partly out of track frame (3) using crowbar. Move track

idler , remove track tensioning cylinder (4).

GO TO NEXT PAGE

2-514