TM 5-3895-373-34

2.36

REPLACE/REPAIR TRACK IDLER ROLLER ASSEMBLY - Continued.

C.

INSPECT.

1.

INSPECT

SLEEVE

BUSHINGS

AND

TRACK

SLIDES.

a.

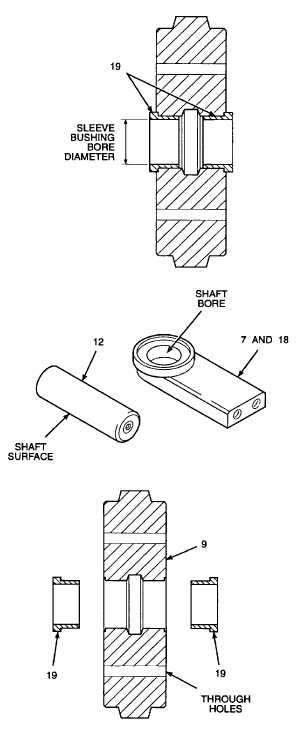

Use slide caliper to measure sleeve bushing (19)

bore diameters near outer edges of bushings. If

either bore diameter measurement exceeds

2.540 in. (64,5 mm), replace both bushings.

b.

Inspect track slide (7 and 18) shaft bores in long

axis of track slide. If the bore is visibly out of

round, replace track slide.

c.

Inspect shaft (12) surface for nicks, scratches or

damage. Use emery cloth to polish out any

raised metal edges. If polishing out does not

effectively repair damage, replace shaft.

2.

REPLACE SLEEVE BUSHINGS.

NOTE

Sleeve bushing should only be replaced

if worn beyond inspection limits. Sleeve

bushings must be replaced as a set.

a.

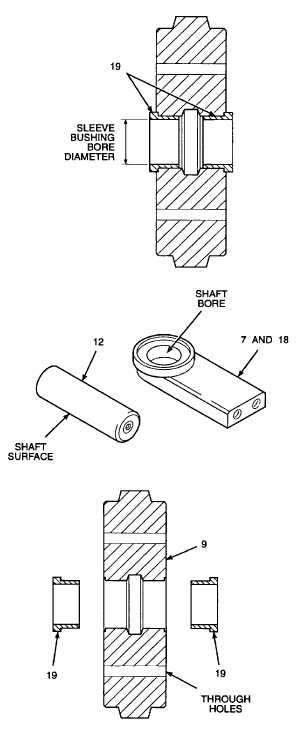

Use internal puller tool from universal puller kit to

remove sleeve bushings (19) from track idler

roller (9).

b.

Install

replacement

sleeve

bushings

with

portable press tools from universal puller kit.

Two 1 in. (25 mm) diameter through holes are

provided in track idler roller (9) for ram press

setup.

GO TO NEXT PAGE

2-510