TM 5-3895-373-34

D.

INSTALL Continued.

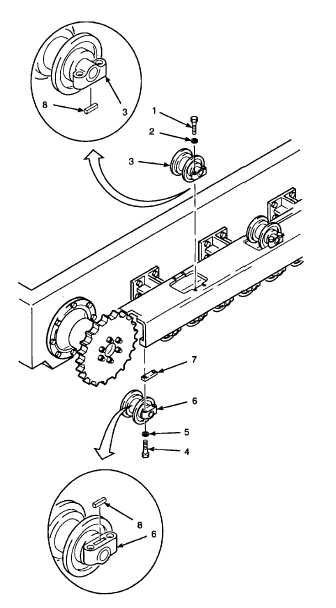

Ensure that before installing the track

rollers that bearing retainer keys are

installed in the track roller mounting pad

and flush with the pad’s machined

surface. Failure to get the key and pad

flush will cause component damage and

track system failure.

c.

Ensure that bearing retainer keys (8) are

installed in track roller (3) mounting pads and

flush with the pad’s machined surface.

Track roller mounting hex head cap

screws must be tightened evenly for

equal clamping loads between roller and

frame.

Failure

to

evenly

tighten

mounting cap screws may result in

shortened roller life.

d.

Install upper track roller (3) and secure with hex

head cap screws (1) and flat washers (2).

Evenly tighten cap screws to 59 Ib-ft (80 N•m).

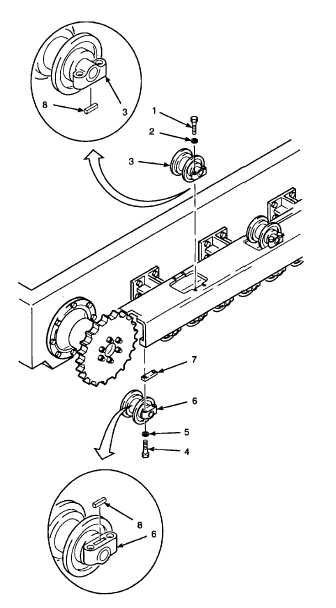

2.

INSTALL LOWER TRACK ROLLER.

a. Install flat washers (5) onto hex head cap screws

(4).

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound contacts

eyes, flush eyes with water and get

immediate medical attention.

b. Apply thread locking compound to threads of hex

head cap screws (4).

c. Ensure that bearing retainer keys (8) are

installed in track roller (6) mounting pads and

flush with the pad's machined surface.

d. Install spacers (7) and lower track roller (6).

Secure with hex head cap screws (4) and flat

washers (5). Evenly tighten cap screws to 59 lb-

ft (80 N•m).

NOTE

FOLLOW-ON-TASKS: Install track chain assembly per paragraph 2.41.

Lower paving machine from jacks per TM 5-3895-373-20.

END OF TASK

2-505