TM 5-3895-373-34

2.30

REPLACE/REPAIR PROPULSION PUMP - Continued.

E.

ASSEMBLE - Continued.

NOTE

Left and right propulsion pumps have hydraulic

fittings in different locations. Each propulsion

pump is addressed in this procedure.

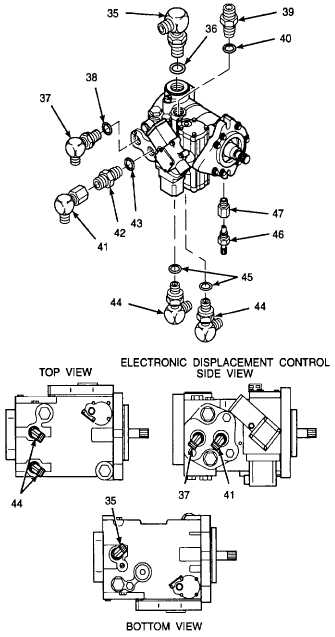

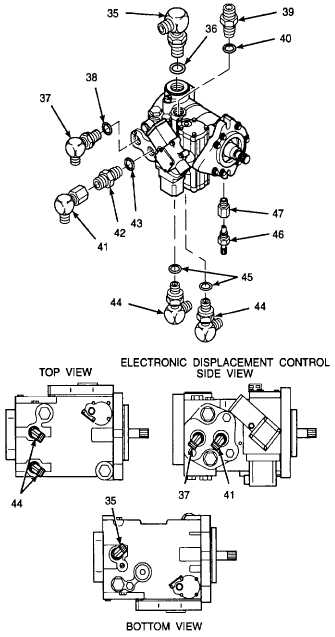

18. INSTALL HYDRAULIC FITTINGS ONTO RIGHT

PROPULSION PUMP.

a.

Remove protective caps.

Hydraulic fitting sealant can cause eye damage

or skin irritation. Wash after skin contact. Wear

safety goggles/glasses when using. Avoid

contact with eyes or skin. If sealant contacts

eyes, flush eyes with water and get immediate

medical attention.

b.

Apply hydraulic fitting sealant to threads of

straight

adapter

(47)

and

hydraulic

oil

temperature sensor (46).

c.

Install hydraulic oil temperature sensor (46) and

straight adapter (47).

d.

Lubricate preformed packings (36, 38, 40, 43,

and 45) with petrolatum.

Be careful not to damage preformed packing

when sliding over threads. Sharp edges of

thread can cut or damage preformed packing.

Damaged preformed packing will cause leakage

and affect performance.

e.

Install preformed packings (45) into packing

grooves of elbows (44). Screw elbows in until

packing meets packing seat in mating port. Aim

elbows as shown in illustration and tighten

locking nut, using combination wrench (Item 116,

Appendix D).

f.

Install preformed packings (40 and 43) onto

straight adapters (39 and 42). Install and tighten

straight adapters.

g.

Install preformed packing (38) into packing

grooves of elbow (37). Screw elbow in until

packing meets packing seat in mating port. Aim

elbow as shown in illustration and tighten locking

nut.

h.

Install preformed packing (36) into packing

grooves of elbow (35). Screw elbow in until

packing meets packing seat in mating port. Aim

elbow as shown in illustration and tighten

locking nut, using combination wrench (Item 116,

Appendix D).

i.

Apply hydraulic fitting sealant to the threads of

straight adapters.

j.

Install elbow (41) onto straight adapter (42). Aim

nut elbow as shown in illustration and tighten.

GO TO NEXT PAGE

2-426