TM 5-3895-373-34

2.30

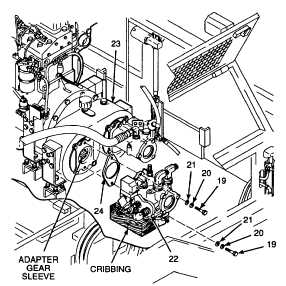

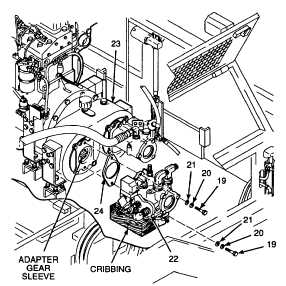

REPLACE/REPAIR PROPULSION PUMP - Continued.

F.

INSTALL.

1.

INSTALL PROPULSION PUMP INTO ENGINE

COMPARTMENT AND INSTALL PUMP ONTO

PUMP DRIVE GEARBOX.

Propulsion pump weighs 75 lbs (34 kg). Place

cribbing beneath pump prior to connecting to

pump drive gearbox. Damage to equipment

and

personnel

injury

may

result

from

unexpected movement of propulsion pump.

NOTE

Left and right propulsion pumps are identical but

the left is inverted from right while mounted on

pump drive gearbox. Procedures for installing

the left and right propulsion pumps are identical.

The right propulsion pump is illustrated in this

procedure; perform the same steps for the left

propulsion pump.

a.

Place cribbing in engine compartment in front of

pump drive gearbox (23).

b.

With

the

help

of

another

person,

install

propulsion pump (22) into engine compartment

and onto cribbing.

c.

Assemble flat washers (21) and lockwashers

(20) onto hex head cap screws (19).

Anti-seize compound can cause eye damage.

Wear safety goggles/glasses when using. Avoid

contact with eyes. If compound contacts eyes,

flush eyes with water and get immediate medical

attention.

d.

Coat splines of pump shaft with anti-seize

compound. If necessary, install adapter gear

sleeve into pump drive gearbox (23).

Thread locking compound can cause eye

damage. Wear safety goggles/glasses when

using. Avoid contact with eyes. If compound

contacts eyes, flush eyes with water and get

immediate medical attention.

e.

Apply thread locking compound to hex head cap

screws.

Uncured gasket sealing compound can cause

eye damage or skin irritation. Avoid contact with

eyes and skin. If compound contacts eyes, flush

eyes with water for 15 minutes and get

immediate

medical

attention.

If

sealing

compound contacts skin, remove from skin with

a dry cloth or paper towel and wash thoroughly

with soap and water. Sealing compound

releases acetic acid while curing. Use with

adequate ventilation.

f.

Apply gasket sealing compound to both sides of

gasket (24).

GO TO NEXT PAGE

2-428