TM 5-3895-373-34

E.

INSTALL - Continued.

Use

care

when

installing

snap

and

retaining rings. Snap and retaining rings

are under spring tension and can act as

projectiles when released and could cause

severe eye injury.

e.

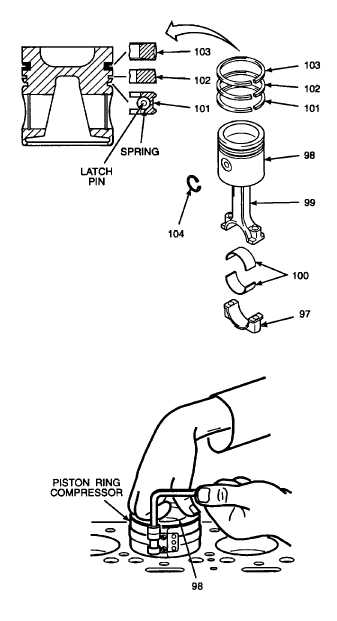

Use inside snap ring pliers to install retaining

rings (104).

f.

Using piston ring expanding tool, install piston

ring (101) on piston, with latch pin entering both

ends of the spring.

g.

Install

piston

ring

(102)

on

piston

with

manufacturer’s mark facing toward top of piston.

h.

Install

piston

ring

(103)

on

piston,

with

manufacturers’s mark facing toward top of

piston.

NOTE

If

sleeve

bearings

are

reused

after

removal, make sure sleeve bearings are

reassembled

in

original

position

as

tagged.

i.

Install sleeve bearings (100) on connecting rod

assembly (97). Ensure oil hole in sleeve bearing

aligns with oil hole in connecting rod assembly.

j.

Lubricate sleeve bearings (100) generously with

engine oil.

7.

INSTALL PISTONS AND CONNECTING ROD

ASSEMBLIES INTO ENGINE.

a.

Lubricate

each

cylinder

bore

and

piston

generously with clean engine oil.

NOTE

Each

piston

and

connecting

rod

assembly must be replaced in the same

cylinder bore from which it was removed.

Use the following list of checks to make

sure piston was assembled correctly, and

is replaced in correct position.

Piston and connecting rod assembly

number

must

match

(1

through

4)

cylinder bore number.

NOTE

Rod identification number must be on

the fuel injection pump side of

connecting rod assembly.

The word "FRONT" marked on piston

crown must point toward front of engine.

b.

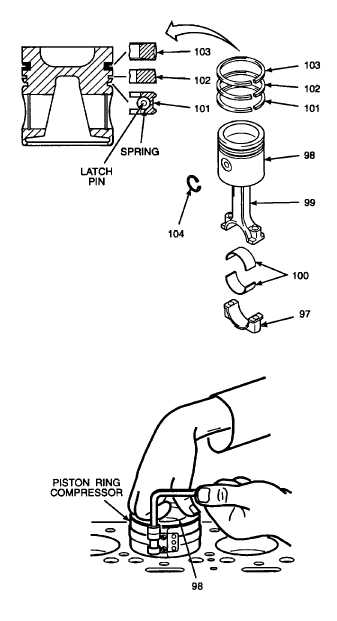

Use a piston ring compressor to insert pistons

(98) into respective cylinder bores.

GO TO NEXT PAGE

2-219