TM 5-3895-373-34

E.

INSTALL - Continued.

e.

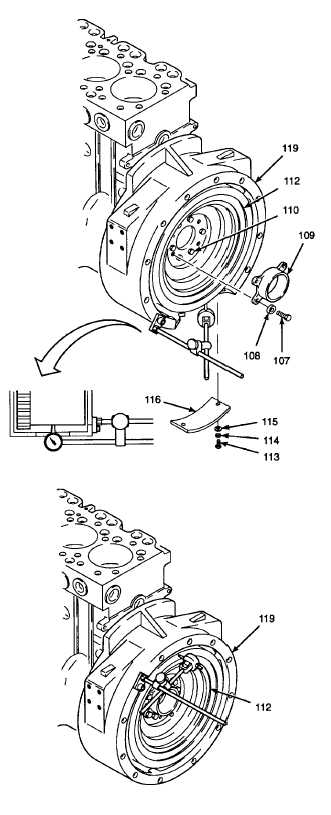

Install a dial indicator onto edge of flywheel

housing (119).

f.

With tip of dial indicator against outer diameter

of flywheel (112), turn flywheel and measure

trueing of flywheel.

g.

Flywheel trueing must be within 0.012 in. (0, 30

mm) of total dial indicator reading.

h.

If flywheel is not within 0.012 in. (0, 30 mm) of

total dial indicator reading, loosen hex head cap

screws (110).

i.

Tap flywheel in opposite direction of higher

reading.

j.

Tighten hex head cap screws (110) to 80 Ib-ft

(108 N.m).

k.

Install housing (109) with flat washers (108) and

screws (107). Tighten to 36 lb-ft (48 N.m).

1.

Install pressure plate (116) and secure with flat

washers (115), lockwashers (114), and hex head

cap screws (113). Tighten cap screws to 80 Ib-ft

(108 N.m).

m.

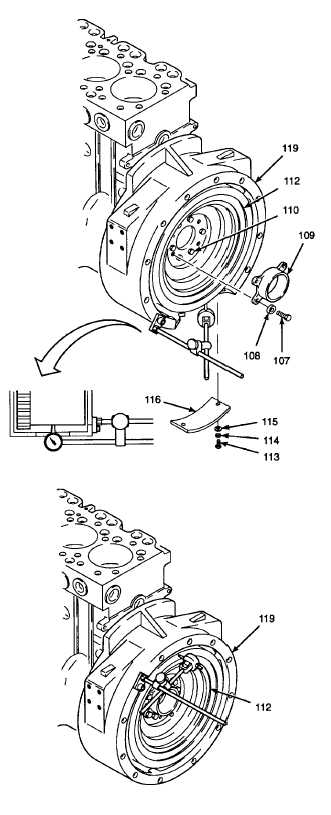

Press flywheel (112) toward engine block to take

up crankshaft assembly end float.

n.

Use dial indicator, attached to edge of flywheel

housing (1 19), to measure outermost point of

machined face runout of flywheel (112), in 1.0 in.

(25, 0 mm) increments.

o.

Flywheel runout must be within 0.001 in. (0, 025

mm) per 1.0 in. (25, 0 mm) of flywheel radius

from crankshaft assembly axis to dial indicator

tip.

p.

If flywheel is out of tolerance, replace flywheel

(112) or crankshaft assembly.

q.

Remove dial indicator.

GO TO NEXT PAGE

2-217