TM 5-3895-373-34

E.

INSTALL - Continued.

g.

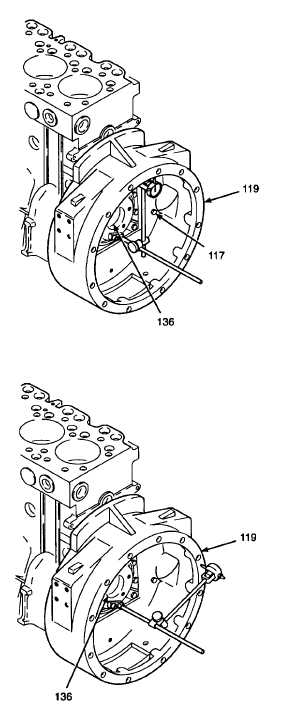

Attach a dial indicator to end of crankshaft

assembly (136).

h.

Measure

concentric

alignment

of

flywheel

housing

(119)

from

center

of

crankshaft

assembly.

i.

Flywheel housing (119) concentric alignment

must be within a total reading of 0.008 in. (0, 20

mm) from center of crankshaft assembly.

j.

If flywheel housing is not within a total reading of

0.008 in. (0, 20 mm), loosen bolts (117).

k.

Use a soft head hammer to tap flywheel housing

(119) in direction of lower reading.

1.

Tighten bolts (117) to 36 lb-ft (48 N.m).

m.

Repeat until flywheel housing is in tolerance or

replace flywheel housing.

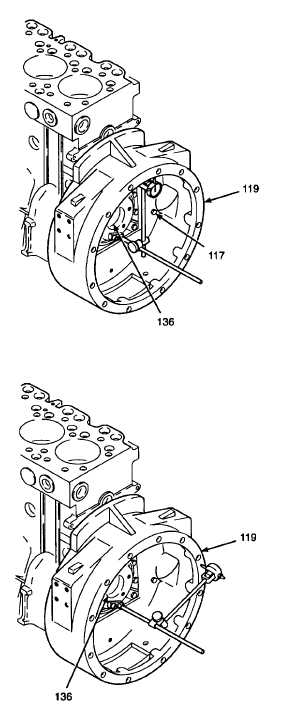

n.

Use

dial

indicator,

attached

to

crankshaft

assembly

(136),

to

measure

perpendicular

alignment of flywheel housing (119) from center

of crankshaft assembly.

o.

Flywheel housing (119) must be within a total

reading of 0.008 in. (0, 20 mm) limit from center

of crankshaft assembly.

p.

If flywheel housing is not within a total reading of

0.008 in. (0, 20 mm), ensure rear face of engine

block and mating face of flywheel housing are

clean.

q.

Recheck perpendicular alignment.

r.

If flywheel housing is still not within tolerance,

replace flywheel housing.

GO TO NEXT PAGE

2-215