TM 5-3895-373-34

E.

INSTALL - Continued.

Do not damage gear shaft threads and

needle bearings when installing gear

shaft into oil pump. Oil pump damage

and engine damage may result from a

damaged gear shaft. Slide gear shaft

slowly into oil pump when installing.

1.

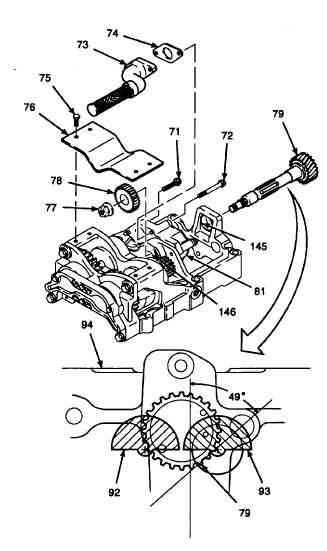

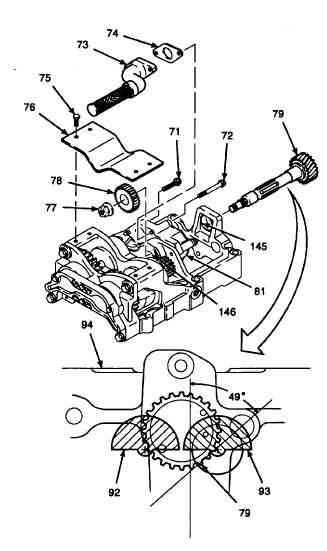

Lubricate needle bearings (145 and 146) with

clean lubricating oil.

m.

Turn spur gears (93 and 92) until flat areas are

aligned with one another, with both weighted

ends facing directly up. Use a small piece of

wood wedged between gear teeth to maintain

this position, if required.

n.

Position gear shaft (79) to its timed position, with

both holes in gear shaft outside face at a 490

angle, smaller hole on right, pointing up.

o.

Install gear shaft (79) through oil pump (81),

keeping holes in face of gear shaft at a 49°

angle, with smallest hole on right, pointing up.

Thread locking compound can cause eye

damage. Wear safety goggles/glasses

when using. Avoid contact with eyes. If

thread locking compound contacts eyes,

flush eyes with water and get immediate

medical attention.

p. Apply thread locking compound to both splines

of gear shaft (79).

NOTE

Keep

torque

wrench

and

crowfoot

wrench at a 90° angle to one another

when tightening hex nut (77).

q.

Install spur gear (78) and hex nut (77). Hold

gear shaft (79) by inserting an aligning punch

into hole(s) in outside face of gear shaft. Use a

socket wrench adapter and a crowfoot wrench to

tighten hex nut to 70 Ib-ft (95 N•m).

r. Ensure gear shaft (79) turns freely in oil pump

(81).

s. Install balancer unit cover (76) hex head cap

screws (75). Tighten to 8 Ib-ft (10 N.m).

t. Install gasket (74), tube (73), machine screws

(72), and hex head cap screws (71). Tighten

machine screws to 22 lb-ft (30 N•m).

GO TO NEXT PAGE

2-223