TM 5-3895-373-20

15.20. ADJUST AND ALIGN MAIN AND EXTENSION SCREED PLATES - Continued.

C.

ALIGN Continued.

Screed

operations

present

a

crushing hazard. Stay clear of screed

during screed operations. Failure to

do so may result in death or serious

injury.

NOTE

Cribbing is used under the screed

only as a safety precaution. Do not

lower the screed onto the cribbing.

Cribbing

may

have

to

be

repositioned

during

alignment

procedure to allow for placement of

straightedge

and

to

view

measurement points.

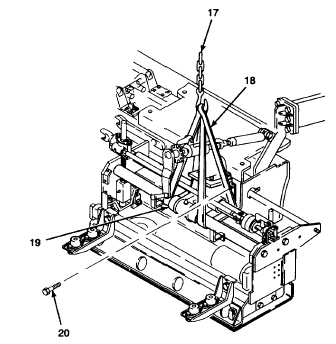

n.

Attach overhead hoist (17) and sling straps (18)

to guide shaft support (19).

o.

Take up slack in sling strap (18) and loosen hex

head cap screws (20).

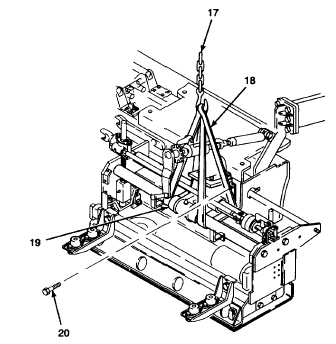

p.

Place straightedge (10) along trailing edge of

extension screeds at A-A. Raise or lower end of

extension screed to obtain a reading of less than

0.060 in. (1,5 mm). Tighten hex head cap

screws (20).

q.

Lower overhead hoist (17) and remove sling

straps (18).

r.

Repeat steps a through q until proper alignment

is achieved.

s. Connect inboard to outboard extension screed

height adjustment knobs if separated in step d.

(Refer to TM 5-3895-373-10.) t. Start paving

machine engine and position extension screed

halfway per TM 5-3895-373-10.

u.

Shut down paving machine and remove key

from ignition per TM 5-3895-373-10. Position

cribbing under screed.

NOTE: HEX

HEAD

CAP

SCREW

IS

SHOWN

REMOVED FOR CLARITY. DO NOT REMOVE

DURING PROCEDURE.

GO TO NEXT PAGE

15-144