TM 5-3895-373-20

15.20. ADJUST AND ALIGN MAIN AND EXTENSION

B. ADJUST-Continued.

Screed

operations

present

a

crushing hazard. Stay clear of screed

during screed operations. Failure to

do so may result in death or serious

injury.

NOTE

Cribbing is used under the screed

only as a safety precaution. Do not

lower the screed onto the cribbing.

Cribbing

may

have

to

be

repositioned

during

alignment

procedure to allow for placement of

straightedge

and

to

view

measurement points.

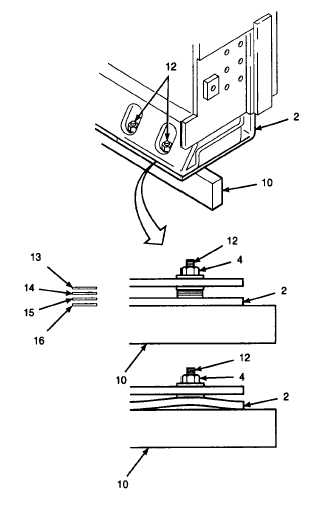

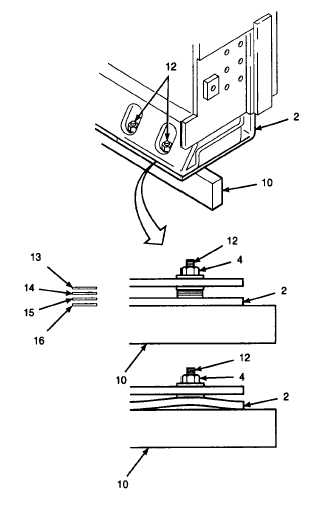

a.

Place straightedge (10) along trailing edge of

screed plate (2) in line with screed plate studs

(12). Have one person support each end of

straightedge.

b.

Measure for gaps between screed plate (2) and

straightedge (10) at each trailing edge stud (12).

NOTE

Shims and plate spacers may be

removed to lower a high point in the

screed

plate.

Follow

the

same

instructions except remove shim(s)

and plate spacer(s) to get screed flat.

c.

If gaps exist, select minimum combination of

shims (13) and plate spacers (14 through 16) to

fill each gap.

Place shims and plate spacers in gaps between

straightedge (10) and screed plate (2) to select

shims and plate spacers.

d.

Loosen self-locking nuts (4) on each stud (12)

that requires shimming and on the studs on

each side of the stud to be shimmed.

e.

Use a hammer and tap a pry bar between

screed plate (2) and screed near stud where

plate spacers are to be added.

f.

Insert selected shim (13) or plate spacer (14, 15,

or 16) between screed plate (2) and screed.

g.

Tap pry bar out of screed. Tighten self-locking

nut (4) to 37 lb-ft (50 N•m).

h.

Place straightedge (10) along trailing edge of

screed plate (2). Measure for gaps between

screed plate and straightedge at each stud (12)

shimmed.

i.

Repeat steps a through h as required to obtain

trailing edge flatness within 0.0625 in. (1,588

mm) for main and extension screed plates.

GO TO NEXT PAGE

15-140