TM 5-3895-373-20

C.

ALIGN - Continued.

WARNING

Screed

operations

present

a

crushing hazard. Stay clear of

screed during screed operations.

Failure to do so may result in death

or serious injury.

NOTE

Cribbing is used under the screed

only as a safety precaution. Do not

lower the screed onto the cribbing.

Cribbing

may

have

to

be

repositioned

during

alignment

procedure to allow for placement of

straightedge

and

to

view

measurement points.

NOTE

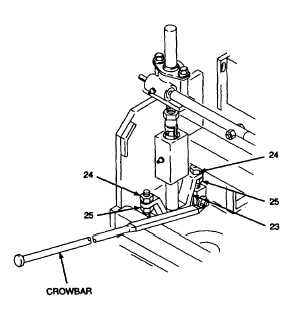

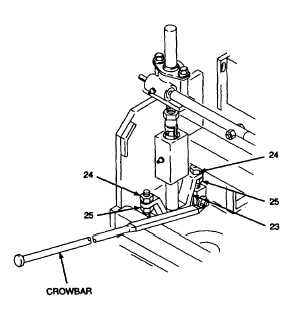

It may be necessary to use pry bar to

raise lift bracket (23) to relieve

pressure on hex nuts (24 or 25) to

allow

for

ease

in

making

adjustments.

e.

Using crowfoot wrench, loosen hex nuts

(24) and adjust hex nuts (24 or 25) at front

or rear of lift bracket (23) to align extension

screed plate angle resulting in an equal

reading at B-B and C-C. If required, adjust

setting in step d. Continue adjusting hex

nuts (24 and 25) and screed height

adjustment knobs to obtain 0.125 to 0.19

in. (3,2 to 4,8 mm) height difference

between leading edge and trailing edge of

extension screed plate.

f.

Tighten hex nuts (24 and 25) without

changing angle of extension screed plate.

g.

Adjust extension screed height adjustment

to level trailing edge of extension screed

plates with trailing edge of main screed

plate at points B-B and C-C.

h.

Measure leading edge of extension screed

measurements B-B and C-C for 0.13 to

0.19 (3,2 to 4,8 mm) height difference

between leading edge of extension screed

plates and trailing edge of screed plates.

Repeat steps c through i as needed.

WARNING

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

i.

Loosen hex nuts (24) enough to apply

thread locking compound. Tighten hex

nuts (24) to 37 lb-ft (50 N•m).