TM 5-3895-373-20

C.

INSTALL - Continued.

2.

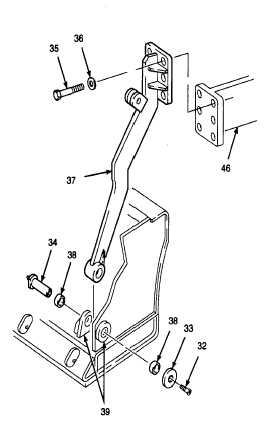

INSTALL SCREED ARM.

a.

Install sleeve bushings (38) into main screed

pivot bores (39). If necessary, use a plastic

hammer to drive bushing flush with main screed

pivot bores.

b.

Install flat washers (36) onto hex head cap

screws (35).

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

c.

Apply thread locking compound

(Item

12,

Appendix C) to threads of hex head cap screws

(35).

Tow arm is heavy. Use another

person to help support tow arm

during installation. Failure to do so

could result in serious injury to

personnel or damage to equipment.

d.

Attach screed arm (37) to tow arm (46) using flat

washers (36) and hex head cap screws (35).

Using socket wrench adapter, tighten cap

screws to 180 lb-ft (244 N-m).

e.

With the help of another person, line up screed

arm pivot boss with main screed pivot bores

(39).

f.

Rotate flats of pivot pin (34) to vertical. From

inside of main screed, install pivot pin in pivot

bores.

g.

Apply thread locking compound

(Item

12,

Appendix C) to threads of socket head cap

screw (32).

h.

Install retainer (33) and socket head cap screw

(32). Tighten cap screw to 37 Ib-ft (50 N•m).

i.

Lubricate pivot pin (34) with grease until grease

can be seen at bracket joints.

GO TO NEXT PAGE

15-27