TM 5-3895-373-20

15.3.

REPLACE THICKNESS CONTROL COMPONENTS - Continued.

A.

REMOVE - Continued.

2.

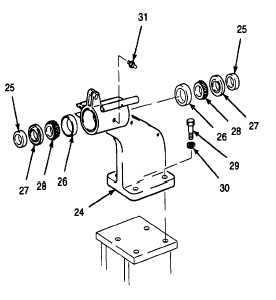

REMOVE

MOUNTING

BRACKET

COMPONENTS.

a.

Insert drive pin punch through center of spacer

(25). Working around outer perimeter of

opposite bearing cup (26), slowly drive spacer,

seal (27), tapered cones and rollers (28), and

bearing

cup

from

mounting

bracket

(24).

Discard plain encased seal and tapered cones

and rollers.

b.

Repeat bearing removal procedure, step a, from

opposite end of mounting bracket.

NOTE

Removal

of

the

following

components is only required when

replacing damaged mounting bracket

or attaching parts.

c.

Remove hex head cap screws (29), lockwashers

(30), and mounting bracket (24). Remove

lubrication fitting (31) from mounting bracket.

Discard lockwasher.

GO TO NEXT PAGE

15-22