TM 5-3895-373-20

15.3.

REPLACE THICKNESS CONTROL COMPONENTS- Continued.

B.

CLEAN - Continued.

2.

CLEAN CAP SCREWS AND MOUNTING

HARDWARE.

Thread locking compound solvent

can cause eye damage. Wear safety

goggles/glasses when using. Avoid

contact with eyes. If solvent contacts

eyes, flush eyes with water and get

immediate medical attention.

a.

Use thread locking compound solvent to clean

threads of cap screws and other mounting

hardware. Use a wire scratch brush to remove

any hard deposits from threads.

b.

Dry with a cleaning cloth.

C.

INSTALL.

1.

ASSEMBLE UNIVERSAL JOINT.

a.

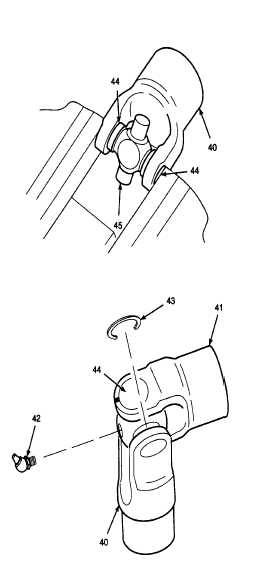

Place bearing assembly (44) in each end of

universal joint yoke (40). Center spider (45)

between bearing assemblies. Make sure that

needle bearings do not fall down in bearing

assemblies.

b.

Place

universal

joint

yoke

(40),

bearing

assemblies (44), and spider (45) in a bench vise.

Tighten bench vise to force bearing assemblies

fully into universal joint yoke.

c.

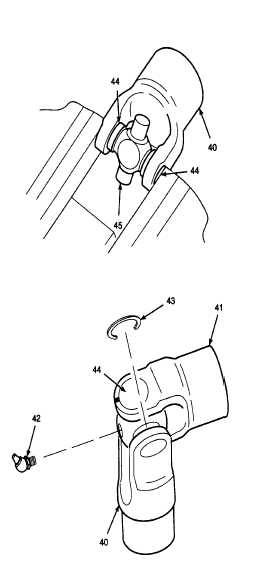

Repeat steps a and b to install bearing

assemblies (44) onto universal joint yoke (41).

Use care when installing snap and

retaining rings. Snap and retaining

rings are under spring tension and

can act as projectiles when released

and could cause severe eye injury.

d.

Place retaining rings (43) in bearing assemblies

(44) retaining ring groove. Using a plastic

hammer, tap retaining ring to drive it onto

bearing assembly. Install all four retaining rings.

e.

Adjust clearance between bearing assembly (44)

and retaining ring (43) by tapping universal joint

yoke with a plastic hammer.

f.

Install lubrication fitting (42) and lubricate with

grease.

GO TO NEXT PAGE

15-26