TM 5-3895-356-14&P

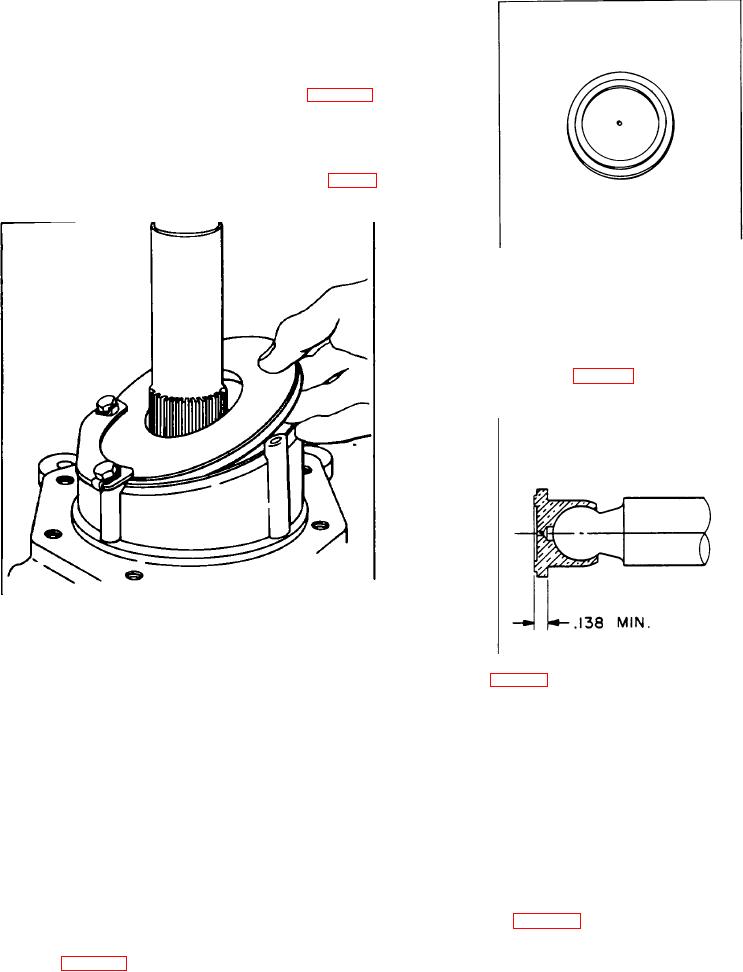

7 Examine wear plate (23) Circular patterns burnished

on the surface of the cam plate are normal

If the circular patterns on the wear plate are extensive

and can be felt with the fingernail or If angular scratches

are evident. the plate must be discarded. See Fig. 210.

8. Match up dowel pin (39) in cam assembly with hole in

wear plate (23) and seat plate (23) In cam. See Fig.21

1.

Figure 212.

Inspecting piston shoe

ON THE LAST FEW PASSES, PLACE 5-6 SHEETS OF

EMERY PAPER AS A CUSHION UNDER THE TOP

SHEET

TO

OBTAIN

THE

PROPER

EDGE

SHARPNESS. Check the reworked piston shoe against

the tolerance limits in Fig. 213. If the piston does not fall

within the tolerance limits, It must be discarded.

Figure 211.

Fig. 123 Installing cam reaction plate

Check for proper seating by pushing down on first one

Figure 213.

edge and then the other in a rocking motion. If any

Fig 125. Piston shoe rework tolerance

looseness is felt, remove the cam plate (23) and clean

the cam assembly and wear plate to remove any foreign

NOTE:

particles from beneath the wear plate. Reposition wear

plate (23) and again check for proper seating. If cam

Often, large scratches on the piston shoe running

plate still does not seat properly, check plate (23) for

surface will "heal over" If placed back In service. It

flatness and replace if necessary.

is recommended however, that all piston shoes

with badly scratched running surfaces be either

9. Check clearance between bronze piston shoe and

reworked within tolerance limits or replaced.

steel piston body (55). With a push-pull motion check for

free play between shoe and body. If any free play can be

11. Inspect steel piston body If any galling Is

felt, the piston must be replaced.

apparent or If any Irregularities can be felt, the piston

must be discarded.

If damage Is present, check

10. Inspect the bronze piston shoe running surface.

corresponding cylinder block bore (40) for similar

During normal service, a dulling of the running surface

damage See Fig. 214.

is to be expected. If large scratches are present, make

several short passes over 500 grit emery paper on a lap

table See Fig. 212.

123