TM 5-3895-356-14&P

SPRAYING

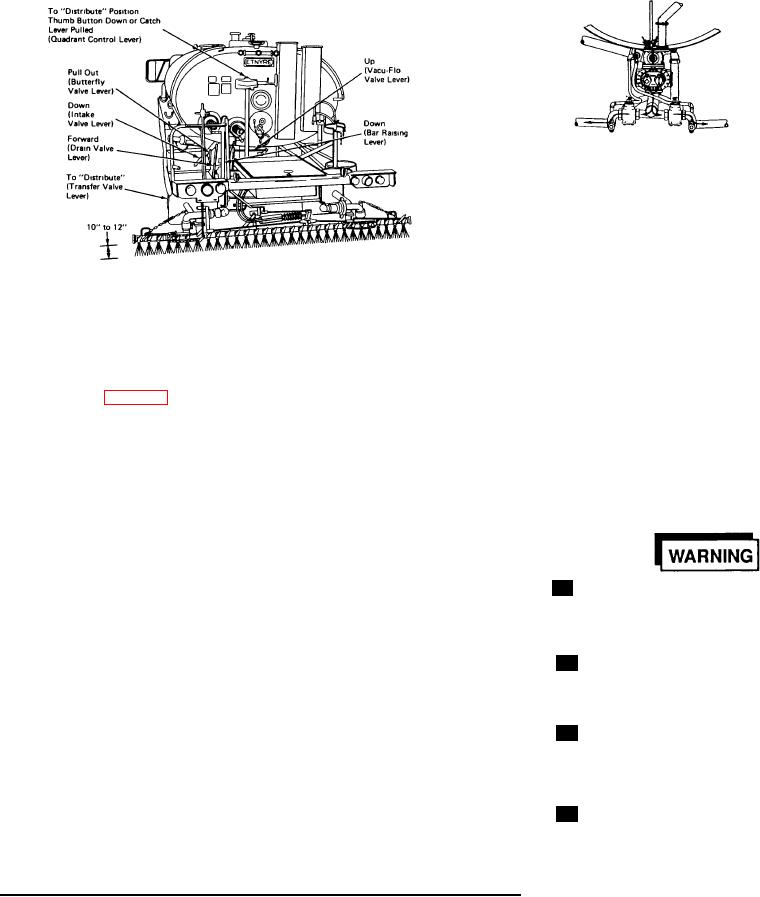

Figure 21.

governor setting Immediately before

4. While spraying, momen-

GENERAL

beginning to spray

tarily drive at dry run speed to check

1. Correct spray cannot be

2. To spray, push thumb button

that bitumeter and pump tachometer

obtained unless bitumen is heated to

down, or pull catch lever, depending

readings

are

still

at

the

proper spraying temperature Cold

on control style, and move quadrant

predetermined ratio. You will apply

bitumen will not give sharp spray

control lever from "Circulate in Bar"

the desired rate per square yard

edges and will cause streaking.

position to "Distribute" position On

regardless of variation in road speed

2. See page 14 "Circulating m

units with one man control, lock

5. To stop spraying, return

Tank" for setting proper pump

thumb button down with "T" shaped

quadrant control lever to "Circulate in

speeds Higher pump speeds will

lever provided *

Bar" position Release thumb button

cause excessive fogging of spray If

3. To stop spraying, return

or catch lever if spraying operation is

higher pump and truck speeds are

quadrant control lever to "Circulate in

completed Pull up hydraulic cab

desired use larger nozzles Lower

Bar" position Release thumb button

control if pump speed exceeds 160

pump speeds will cause fan to sag,

or catch lever, if spraying operation is

G.P M.

with heavy edges

completed Reduce throttle setting if

3. Nozzle slot should make an

pump speed exceeds 160 G P.M.

angle of approximately 30 degrees

with bar centerline and every nozzle

should be at the same angle

Hydrostatic Models

5 Remain clear of rotating drives when

4. Nozzle height of 12" above road

1. Engage truck transmission in

unit is m operation to prevent

will give triple lap coverage

gears previously determined for

becoming entangled m machine

5. With "FC" spray bars do not

proper application speeds

throw control lever to spraying

2. Push hydraulic cab control

7 Monthly check and If necessary

position if end section is folded

down against stop (if it was pulled up

clean 3" overflow tube to insure tube

without first removing shoulder bolt at

to reduce pump speed to 160 G P M

has not become clogged

hinge that controls extension valves.

for circulating in bar). Immediately

6. Dram and flush out pump,

put truck in motion

Keep area clear of open flame or

3. To spray, push quadrant 11 sparks when spraying material with

bar and circulating system after each

days use, unless oil is so light that it

control lever button down, or pull

volatile cutbacks to reduce fire

will not set up when cold.

catch lever, depending on control

hazard

7. Clean pump outlet strainer

style, and move lever from "Circulate

weekly.

m Bar" position to "Distribute" 15 Spray bar on-off operation with air

position On units with one-man

Engine Drive Models

will cause control lever on quadrant

control, lock thumb button down with

1. If throttle was partially closed

to move rapidly Remain clear at all

"T" shaped lever provided *

to limit pump speed to 160 G.P M for

times to prevent injury.

circulating in bar, re-open to proper

*Thumb button or catch lever is used only to engage control for turning spray bar

valves on and off

16