TM 5-3895-356-14&P

on motor shaft (1). using an arbor press CAUTION

an arbor press and 21' Inch plug Fill cavity In shaft

should be exercised not to deform Inner retainer ring (58)

seal between oil lips approximately 34ftull with Litholene

when ball bearing (38) is seated against it If this occurs,

multi-purpose grease. Install new O-ring (57) in flange

back the ball bearing (38) oft and reseat Care should

(2). To prevent possible cuts or abrasion. the O-ring

be taken to support the inner race in the arbor press to

157) should be lightly coated with a multi-purpose grease

prevent deformation of the ball bearing Heating the

bearing In hot oil will aid In a smooth bearing installation

Install outer retainer ring (58).

5. Wrap slim stock or other thin material around shaft

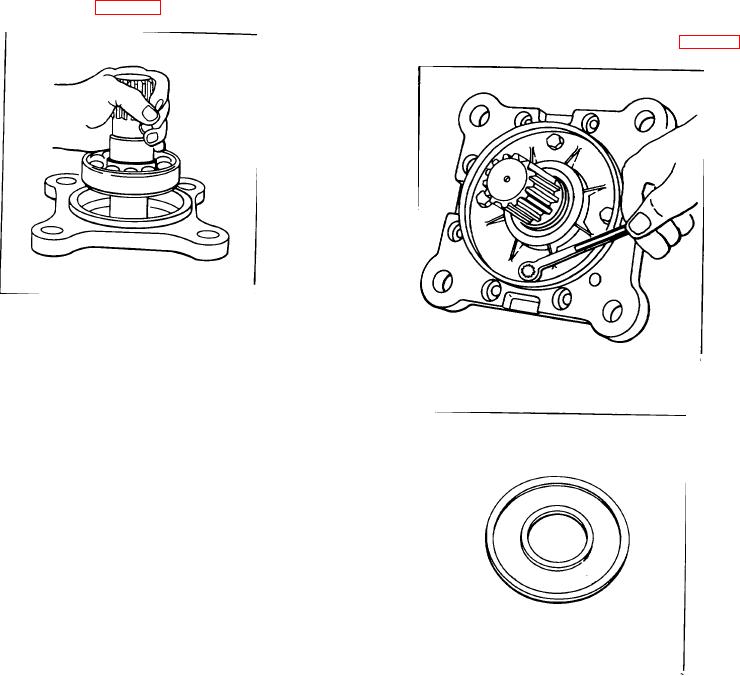

3. Install motor shaft assembly (1, 38, 58, 49 and inner

spline and carefully slide shaft seal (59) and retainer

race of bearing 44) through the front face of the

(60) Into place over motor shaft (1).

mounting flange(2) See Fig. 208.

6. Secure seal retainer (60) with hex bolts (48) and

Lock washers (47) Torque to 132 In. lbs. See Fig 209.

Figure 208.

Installing motor shaft assembly

The ball bearing (38) should fit snugly In the flange (2) If

Figure 209.

the ball bearing (38) doesn't seat easily, heat the

Installing shaft seal retainer

mounting flange (2) in hot oil and seat ball bearing (38) In

proper position DO NOT drive the ball bearing (38) into

place DO NOT use the shaft seal retainer (60) to force

the ball bearing into the seat.

After ball bearing (38) is seated, check for free running

by rotating shaft (1).

c Install shaft seal (I) and retainer (H) with retainer

gasket (E), hex bolts (G), and lock washers (F).

4 Coat the seal 0 D with Loctite pipe sealant and press

new shaft seal (59) into retainer (60) using

Figure 210.

Inspecting cam wear plate

122