TM 5-3895-356-14&P

number one as a method of preserving the bore/ piston

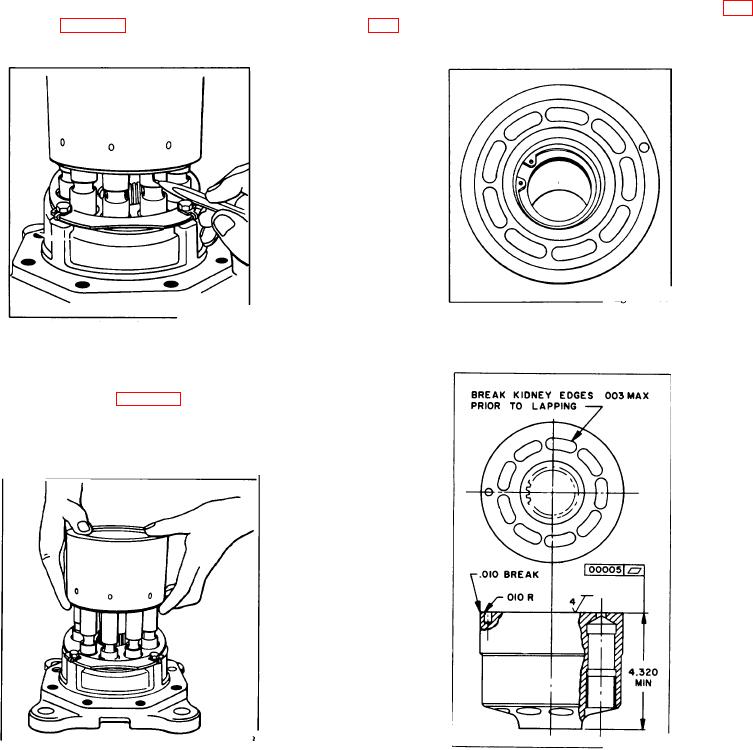

Examine the upper running face of the block. See Fig

relationship See Fig 109. All used pistons must be

199. Circular wear patterns or photographing that cannot

returned to their respective bores upon reassembly.

be felt with the fingernail are normal.

Figure 199.

Figure 197.

Inspecting cylinder block

Marking number one piston

Remove the cylinder block (40) by lifting It straight up off

the piston assemblies See Fig. 198.

Examine the block assembly (37) for excessive wear or

damage

Figure 198.

Figure 200.

Removing cylinder block.

Cylinder block rework specifications

Cylinder bores that exhibit only slight burnishing of the

If the block is acceptable for reuse in all other respects,

bronze liners are acceptable for reuse If the bores

several passes of the block over 500 grit emery paper on

exhibit galling or any other Irregularity In the running

a lap table, is recommended to put the block face in a

surface that can be felt, the cylinder block must be

like-new condition. If circular wear patterns can be felt

discarded. If there is evidence that the bronze liners

with the fingernail, grind the running face as necessary to

have begun to pull out of the steel block, the block must

remove the wear pattern keeping the face parallel to the

also be discarded

original face Lap the reworked face on 500 grit emery as.

119