TM 5-3895-356-14&P

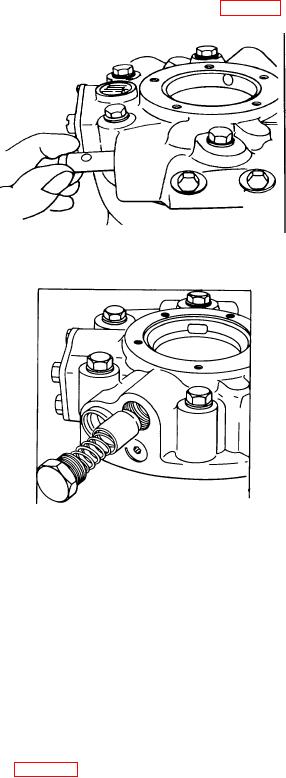

24. If previously removed, Install two plugs (33) with new

NOTE:

O-rings (34).

Units' of recent manufacture utilize male shuttle valves

with female shuttle plugs Older units used female shuttle

25. Install shuttle (32) in cover (4) See Fig 224.

valves and male shuttle plugs Where it becomes

necessary to replace either the shuttle or the plugs, be

certain the faulty piece Is replaced with one of a like kind.

Dynapower motors have been manufactured with three

high pressure relief valve configurations as illustrated

below To complete assembly, identify relief valve

configuration and proceed as Instructed.

Figure 224.

Installing shuttle valve

Figure 225.

Installing low pressure relief valve

Check for free movement from side to side If any

tightness is felt, remove any nicks or burrs with 500 grit

emery It Is essential to the proper operation of the

relief valve system that the shuttle valve operate freely

Install shuttle plugs (35) with new O-rings (17).

26. Inspect low pressure relief valve plunger (61) for

scratches, nicks or burrs. Burnishing of the plunger at

the point of contact with the seat is normal If wear can

be felt, replace the plunger (61) Install the plunger (61),

spring (62), a new O-ring (17), and relief valve plug

(73) See Fig 225.

127