Flat Strike-off Adjusted Too Low

Figure 26

RESULTS OF IMPROPER STRIKE-OFF

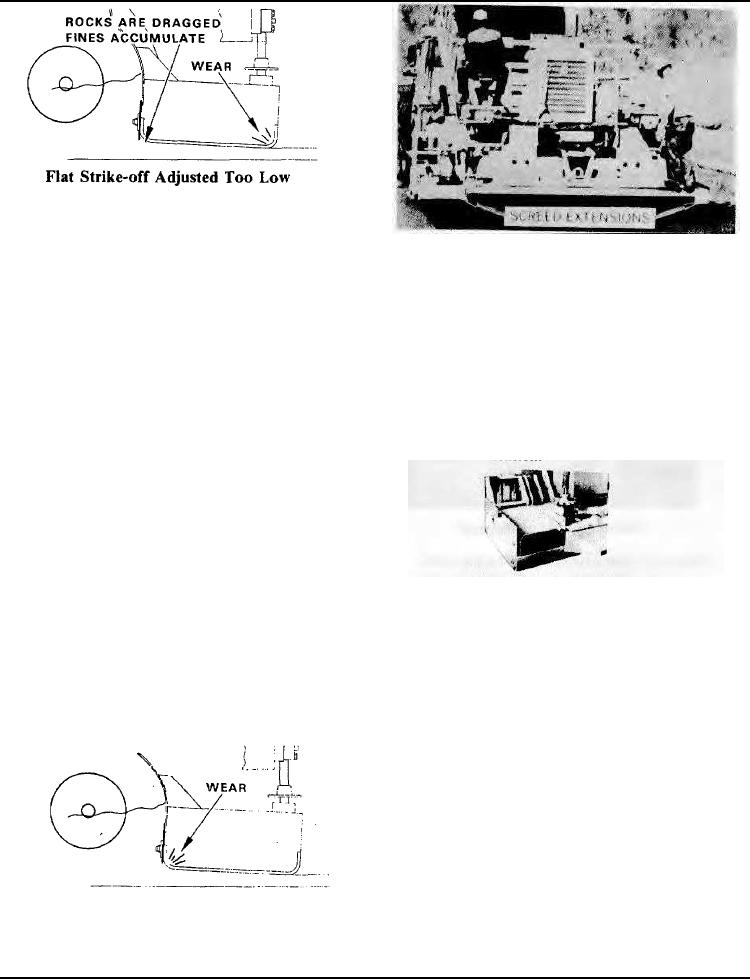

Paving With Extended Screed

When the strike-offs are too low the following wear

Figure 28

and operational difficulties will be encountered. (See

EXTENSION OF SCREED

Figure 26).

The screed length can be extended in order to lay a

1. Insufficient amount of material will be metered

mat wider than 10 ft. Mat widths up to and including

to the screed. Therefore, in order to maintain mat

20 ft. can be laid. Screed extensions come in various

thickness, it is necessary to tip the front of the screed

widths and can be attached to either end of the

up. Continued operation of the screed in this manner

screed.

may cause wear on the trailing edge of the screed.

Each 6", 12" and 24" extension is supplied complete

2. Fines will collect at the front edge of the screed

with cover, moldboard extension, and adjustable

directly behind the strike-offs which will build up and

strike-off extension.

cause tearing and voids in the mat. The strike-off will

frequently catch and drag large stone, with the result

that a streak is made in the mat. When this occurs

often, stop paving, raise the strike-off, and try again.

When the strike-offs are too high the following wear

and operational difficulties will be encountered. (See

Figure 27).

1. Too much material will be metered to the

screed. Therefore, in order to maintain a relatively

thin mat thickness, it is necessary to tip the front of the

12 Inch Extension On LH End Of Screed

screed down with the hand wheel adjustments. With

Figure 29

the screed in this position for any length of time, rapid

All parts of the extension are shipped loose and

wear on the leading edge of the screed will occur.

must be assembled in the field. Some careful work is

2. Poor mat textures and low compaction of the

required to align each extension bottom to the screed

mat will prevail under these conditions.

bottom, the moldboard extension to the moldboard,

3. Erratic control of the screed will be noticeable

and the strike-off plate extension to the strike-off

when making minor adjustments.

plate.

A double set of shim packs is supplied with each

extension so that an adjusted shim pack can be kept

inside the extension at its proper corner location.

(See Figure 30). The lengthy job of fitting the

extension bottom to the screed bottom need not

be repeated each time the extensions are

installed. Re-installation of the two correct shim

packs will quickly restore alignment and no time is

lost. The moldboard shims can also be attached at

their respective locations to save time aligning the

extension moldboard.

Flat Strike -off Adjusted Too High

A step by step procedure for assembly and

Figure 27

installation of an extension is shown on the following

pages.

Page 62